About us

ROLF SCHLICHT GmbH offers a wide range of system solutions for cutting jobs

We are proud of 60 years of company history.

Quality & Competence since 1959

Trendsetter for 65 years

Presence in more than 60 countries

ROLF SCHLICHT GmbH

Quality and competence since 1959

The graduate chemist Rolf Schlicht, “ingenious inventor” and “agile maker” with very close contacts to the rubber and cable industry; founded in 1959 the ROLF SCHLICHT GmbH and is constantly looking for partners, with the help of which he can meet the needs of its customers. This results in development, manufacturing and sales partnerships, some of which are still valid today.

Together with Alberto Bocca, the founder of SAGITTA s.p.a, Italy, he already gained his first experience in powdering of talcum and other powders used as release agents in the rubber and cable industry in the early sixties. On the jointly developed band granulators, the first powdering units “Talk-U-mat” are used. (“Talc and automation”).

This encounter lays the foundation for the success of the brand “RS POWDERTECH” powder coating equipment. Even today, SAGITTA is closely associated with ROLF SCHLICHT.

Today, ROLF SCHLICHT GmbH develops, manufactures and sells machines and systems for the cable, rubber and plastics industries worldwide. In addition to our own brands RS POWDERTECH for powder coating systems and RS MULTICUT for cutting and further processing solutions in the extrusion sequence, a wide range of machines from various well-known manufacturers around the cable, rubber and plastics industry is offered.

Market leader for over 50 years

Trendsetter for 65 years

Presence in more than 60 countries

Founded

ROLF SCHLICHT GmbH

60 Years company history

1959

Foundation of ROLF SCHLICHT GmbH by graduate chemist Rolf Schlicht. Due to good contacts to the rubber and cable industry, the technical trading house specializes in these industries. In addition to in-house developments of machines in this environment, a number of representations of well-known, international manufacturers are taken over (see below).

1959

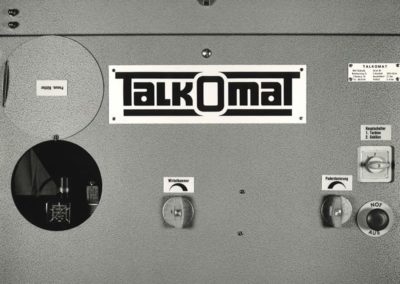

Rolf Schlicht, a graduate chemist and inventor, is constantly looking for partners with whom he can put his ideas and solutions into machines together. Together with Alberto Bocca, founder of SAGITTA / Italy, he developed band granulators for the precise granulation of rubber compounds in the early 1960s. This is the foundation stone of the powdering units. On the band granulators, the first powder units with the name “Talk-u-mat” (talc and automation) are installed.

1969 – 1979

From 1969 to 1979 the company ROLF SCHLICHT GmbH represents the company CHANDOR / Great Britain for simple powdering units.

1979 – Admission of the sons Michael and Joachim Schlicht. Under their leadership, the company has steadily established itself as a trusted global partner for the supply of machinery to the cable, rubber and plastics industries.

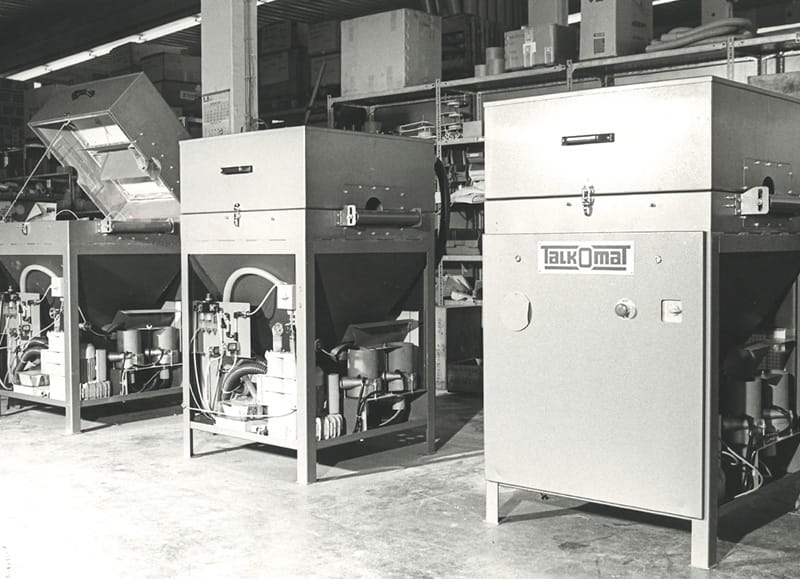

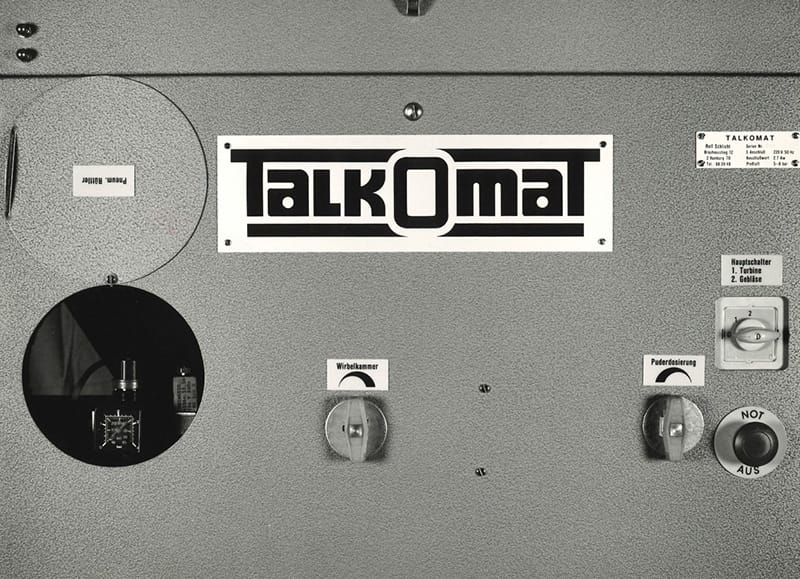

1980

Start of the development of powder coating machines for continuously running strands. Under the protected name “Talk-O-mat” the first automated powdering units are sold. Construction and production are implemented with a partner in Hamburg / Oststeinbek. The optimized variant will later be distributed under the name “TALKATOR“. A dust-free way of working is the stated goal right from the beginning.

1982

Foundation of the subsidiary “USD Gebrauchtmaschinen für Gummi und Kunststoff GmbH” with a focus on used machinery for the rubber, plastics and cable industries

1993

The powder coating unit RS 80 (“TALKATOR 2000”) is designed and built together with a partner in Reinfeld / Schleswig Holstein.

1995

Founding of the subsidiary SCHLICHT Handelsgesellschaft oHG. Focus on cleaning technology and dosing systems for the plastics industry.

1997

With the PBA / RSC series, the success story of the powder coating systems continues at ROLF SCHLICHT GmbH. Together with a specialized machinery factory near Hamburg, the RS 80 is adapted to the increased requirements of the market and redesigned. (PuderBeschichtungsAnlage / Rolf Schlicht Coating).

1997

In this context, the powder coating system is being expanded for a variety of applications: from extra-narrow or free-standing powder chambers to high-speed powder chambers, a wide range of solutions is offered for the cable and rubber industry. Under the brand “RS POWDERTECH“, the systems are sold through a worldwide dealer network. In some cases, the distributor partnership exist for more than 30 years.

1997

Move from Brauhausstieg / Hamburg to larger and more modern business premises in Hamburg Rahlstedt. Higher inventories of spare parts and a testing lab for even more customer care than before.

2001

Start of construction of high-precision cutters, caterpillars and pullers under the brand RS MULTICUT for the plastic and rubber extrusion. Together with a partner near to Hamburg, the machines are designed and built. ROLF SCHLICHT GmbH employs a global network of agents in addition to the German sales location for the sale of its own machinery.

2009

50 years ROLF SCHLICHT GmbH – 50 years of innovation

ROLF SCHLICHT GmbH celebrates its 50th anniversary. After more than 50 years of company history, ROLF SCHLICHT GmbH employs ten people.

2016

After nearly 40 years of activity, Michael and Joachim Schlicht hand over the company to the “3rd generation”. New managing partners will be Lars Bochmann and Heiko Heynen. But Michael and Joachim Schlicht still provide support and advice. In December 2016 Michael Schlicht leaves the company. As part of Bochmann Holding GmbH, ROLF SCHLICHT GmbH is now able to offer further engineering capacities and an electrical engineering laboratory.

2017

Relocation of the company headquarters from Hamburg to Reinfeld / Schleswig-Holstein. Significant expansion of office, workshop, laboratory and warehouse capacities. Five companies united under one roof. With the move to the new business premises, also Joachim Schlicht leaves the company.

2019

60 years of Quality & Competence, ROLF SCHLICHT GmbH as an innovation driver and market leader. Successful launch of the new powder machine model RSC-NG (next generation) on the market. After the RSC, which was introduced in 2004, a huge leap in innovation thanks to a completely redesigned e-static and filter system.

2019

Successful relaunch of the complete RS MULTICUT program.

MC NG now as a high speed and with high precision cutting bushes for absolute angularity of the cut and parallelism.

Relaunch of the OC 30 NG as a completely new development, also availabe as high speed version. Higher reliability and significant price advantage compared to the old OC models.

2020

Presentation of the new developments TLKTR SPC for strands, profiles and cables as well as the TLKTR DR for powdering small parts and granules.

2020

Presentation of the newly programmed HMI / PLC control. Now with significantly improved user-friendliness. Functionality of the line speed dependent powdering and recipe control improved.

2020

Introduction of the new OC-70 NG as a completely new design with considerable advantages compared with the old OC-65.

Relaunch of the completely revised RSC-30 NG high speed. After 10 years of successful market presence, now with new e-statics, a new filter system and many other improvements.

2020

Presentation of the CCH-XX, a combi-cutting unit with an integrated heating tunnel for cutting brittle and tough materials with perfect cuts.

2023

With the FLEXILINE, ROLF SCHLICHT is entering a new era of cutting machines in 2023.

Completely new design, consistent modular system, stainless steel bodies, new control systems in three equipment variants.

2024

65 years of ROLF SCHLICHT GmbH – 65 years of Quality & Competence

ROLF SCHLICHT GmbH celebrates its 65th anniversary. The company has changed significantly, all processes are again united under one roof. The modern and cosmopolitan company now employs employees from a wide variety of countries.

2024

With the LCC series, ROLF SCHLICHT 2024 is breaking new ground in the field of powdering machines.

The LCC series (E-Static Machine) is a new design with a focus on high quality for low investment costs. Giving the customer exactly what they need.

Representation of international manufacturers

Due to good contacts to the rubber and cable industry, ROLF SCHLICHT GmbH specializes in these branches of industry. In addition to in-house developments of machines in this environment, the technical trading house represents a number of well-known, international manufacturers over the years. Amongst others:

- SAGITTA / Italy (Band granulators, transport and depowdering systems. Horizontal splitting machines for rubber and plastic. Cutting machines for manufacturing gasket rings from rubber sleeves and hoses.)

- HUESTIS INDUSTRIAL / USA (Air wipes for blowing and drying. Cable strippers.)

- BATTAGGION / Italy (Sigma und Z-kneader, granulating systems, twin screw extruders mixing mills, extruder for silicone processing)

- MOLTENI / Italy (Planetary mixer for chemical, food, pharmaceutical, cosmetics, rubber and plastsics industrie. A subsidiary of Battaggion group.)

- VALTORTA / Italy (Turbo mixer, high speed mixer, vacuum dryer, mixing lines, kneader and planetary mixer. A subsidiary of Battaggion group.)

- NORMEC / Norway (Machines and systems for joining rubber and silicone profiles, as well as moulds. Delivery of rubber film 0,2 – 0,6 mm.)

- PUMATECH / Italy (Rubber-bale cutters, strip cutters, cryogenic deflashing systems.)

- WALLACE / Großbritannien (Design and manufacture of instruments and rubber testing equipment that measure physical properties such as hardness, plasticity, viscosity, hardening, compression and many other properties).

- MARIS / Italy (Co-rotating twin screw extruders for high-quality continuous mixing of plastics and rubber, as well as for recycling or upcycling processes.

- FONTIJNE / The Netherlands (Laboratory plate presses for the preparation of test plates for material testing on standardized test specimens in many production areas such as rubber, plastics, composites, but also e.g. in the wood industry, for laminates, etc.).

- ARISTO Cutting Solutions / Germany (Flatbed cutters. Reliable and high-precision processing of composite materials such as carbon, prepreg, glass fiber and other fiber composites. A subsidiary of ROLF SCHLICHT GmbH).

- BARWELL Global Limited is a world leader in the manufacture, design and supply of high quality and versatile rubber processing machinery. Barwell Global Limited offers equipment for any type of production method. Whatever your requirements and production methods (compression, transfer or injection) and whatever your compounds (silicone, NBR, CR, SBR, from EPDM to FKM),

- IMG covers the entire injection and compression molding range of elastomers and thermosets for the most demanding manufacturers. More than 14 different machine models, including fully electric systems.

- And more…

Contact us

Write to us by using the contact form or call us. We are happy to advise you.

Call us now

Contact us

Write to us by using the contact form or call us. We are happy to advise you.

Call us now

Our headquarters

Grootkoppel 16, 23858 Reinfeld, Germany

opening hours

Mon-Thu: 8:00 - 16:30

Fri: 8:00 - 16:00