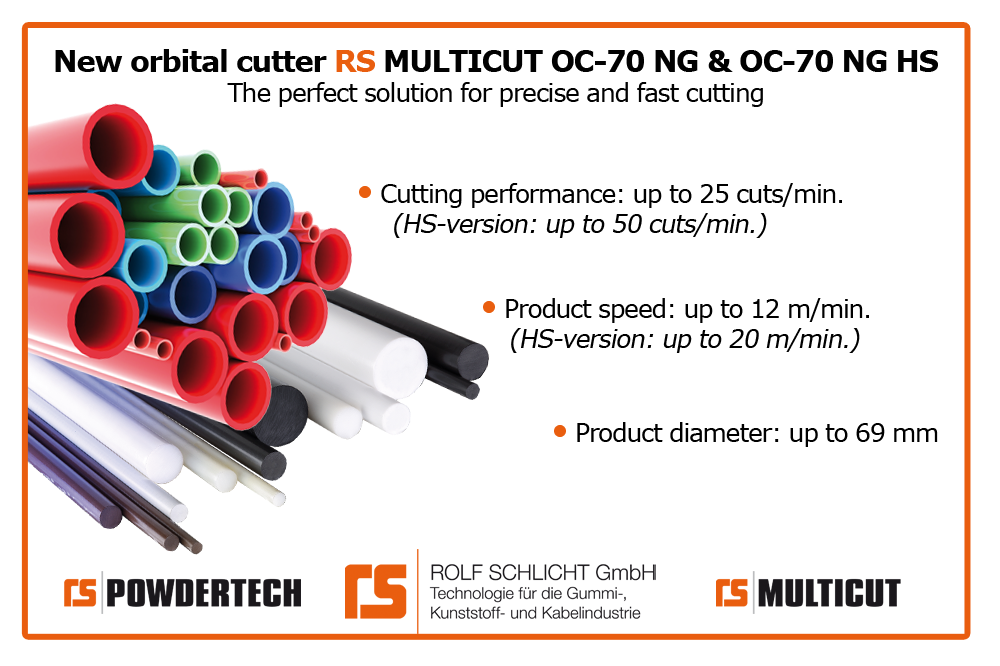

The newly developed orbital cutter MULTICUT OC-70 NG (next generation) is perfectly suited for semi-hard and hard pipes with a diameter of 5 to 70 mm for high line speeds

Get to know the completely new orbital cutter RS MULTICUT OC-70 NG.

The cutting machine was redeveloped in 2020 and works with a significantly higher level of precision and speed than ever before. The OC-NG – “next generation” series not only comes with a significantly improved functionality, but has also a very attractive new pricing. The RS MULTICUT OC-70 NG is significantly cheaper than previous OC-versions. An investment that pays off.

The OC-70 NG is suitable for semi-hard and hard pipes with a diameter of 5 to 70 mm.

The cutting system impresses with a clean and absolutely right-angled cut on the fly and works completely chip-free. The orbital cutter is ideally suited for the precise and fast cutting of semi-hard and hard pipes made of different materials such as plastic, rubber, plastic composite with aluminum, rubber with Kevlar, etc.

Thanks to a standard servo linear drive for the tool carrier, the moving cutting unit achieves excellent cutting quality and, at the same time, short cycle times for processing high line speeds.

All important cutting parameters can be adjusted during the process using a PLC control. Thus, the cutting system can be optimized with ease according to the requirements and specifications. The new OC-70 NG extrusion downstream machine is offered in the usual quality, but now at a particularly attractive price, and is also available as a high-speed version OC-70 NG HS. This revolutionary cutting system replaces conventional processes such as saws, guillotines etc. The OC-30 NG and OC-30 NG HS are available in the portfolio for smaller diameters up to 30 mm. Do you work with a different product diameter and need a special solution tailored to your product? ROLF SCHLICHT GmbH develops and produces cutting systems for special sizes, also on customer request. The sales team looks forward to your inquiry.

The most important parameters can be found in the features listed below:

OC-70 NG (OC-70 NG HS)

- Product speed: 12m/min (max. 20 m/min)

- Product diameter: 69 mm

- Cutting performance: 25 cuts/min. (max. 50 cuts/min)

(depends on material) - Number of orbital rotations: 3 each cut

- Cutting motor: Servo-drive

- Material thickness: 6,00 mm max.

- Operation of the blade: mechanically by gear motor drive

- Connection values: 3~400 VAC, 50/60 Hz, 16 A

- Control: Siemens S7

The sales team at ROLF SCHLICHT looks forward to your inquiry and is at your disposal at any time if you have any questions or for further information.

Your contact person: Mark de Nooijer sales @schlicht-gmbh.de +49 4533 6063-100

Follow us on LinkedIn and learn more about ROLF SCHLICHT: