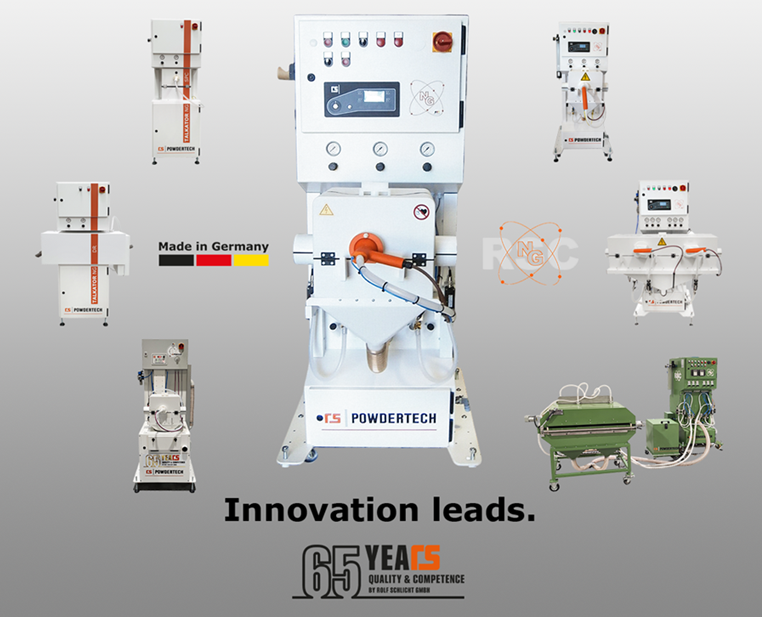

RS Powdertech

The world’s largest range of electrostatic, tribostatic and pneumatic powder coating systems for dust-free and finely dosed powdering of cables, wires, hoses, profiles and tapes with all common powders.

Quality & Competence since 1959

Trendsetter for 65 years

Presence in more than 60 countries

RS Powdertech

Electrostatic and pneumatic powder coating machines

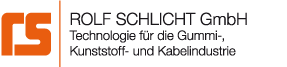

RSC – NEXT GENERATION

The RSC NG Series combines knowledge and development from 1959 to the present day. With the complete redevelopment of the electrostatics, the series has offered since 2018 the most modern, safest and most reliable E-statics for talc coating on the market.

Stearates can be processed without fire suppression. The gun is virtually indestructible with “RS cooling technology” and in the new compact version provides improved handling and better coating results.

The durability and reliability of the components have been significantly improved. The completely redesigned filter system leads to enhanced cleaning performance with reduced maintenance costs thanks to fewer wear parts. Higher reliability and the well-known high powdering quality in terms of adhesion ensure optimum production results.

Since 2018 the most modern, safest and most reliable electrostatics (with higher adhesion)

Completely newly developed E-static system (higher adhesive force)

Absolutely dust-free operation

1 – 4 powder pistols, 80 kV each pistol (real)

optional: 1-4 x 100 kV each pistol (real) or

1-4 pneumatic nozzles

“Easy Change” filter system

Better cleaning results, less wear parts

Speeds up to 2.000 m/min.

Optionally powder flow control, free-standing powder chamber, micro fine dosing / micro fine dosing plus

Optionally fine dosing / fine dosing plus

Poka Joke principle for pistol spare parts

LCC Series – entry level, electrostatic powdering machine

The LCC series is an ENTRY LEVEL MODEL in electrostatic, dust-free powdering.

The series closes the gap in the area below all electrostatic systems available on the market today with an unbeatable price-performance ratio. Of course, the whole thing is in the usual high RS quality, but consistently simple and therefore consistently cost-effective!

Despite the unbeatable price, the LCC series has reliable e-statics that charge the powder and offers the advantage of being dust-free thanks to the proven ROLF SCHLICHT filter technology. The tried and tested RS filter technology also uses more than 2/3 less compressed air than comparable systems on the market.

With the LCC series we can offer powdering systems that enable customers with a low budget to enter the world of electrostatic, dust-free powdering.

Completely newly developed LCC E-static system

Dust-free operation thanks to the newly developed LCC filter system

Newly developed LCC powdering “guns” (“EA=Electric Applicator”)

Speeds up to 350 m/min.

optional powder flow control

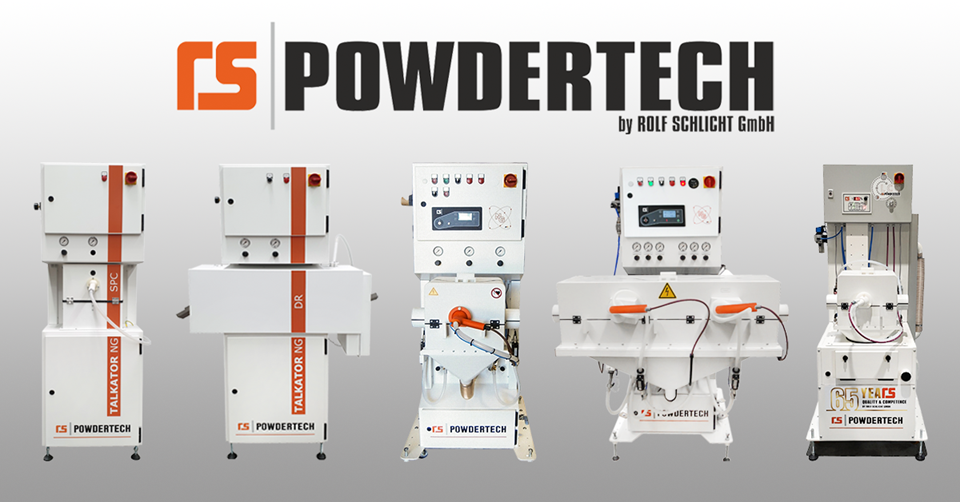

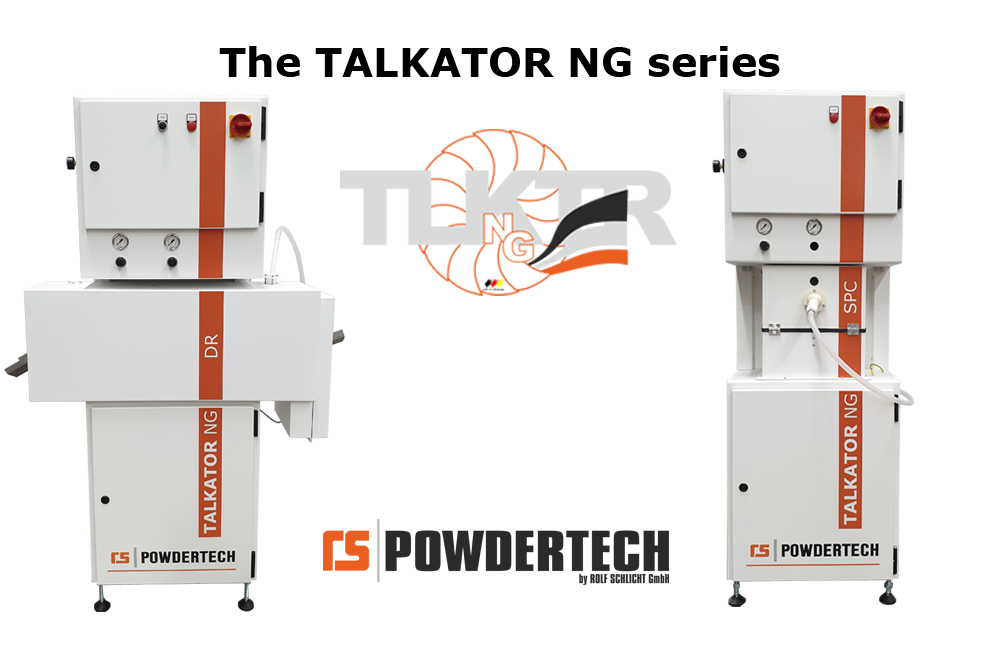

TALKATOR – NEXT GENERATION

TALKATOR and TALK-O-MAT were the first two own machine lines of the company ROLF SCHLICHT GmbH in the 60s to 80s. They are the reason for the worldwide success of the machines.

Based on the simplicity of these old machines we have developed two new attractive products which are used in different areas.

The TALKATOR NG “SPC” for dust-free powdering of cables, hoses, wires and profiles in slow running production processes as well as the TALKATOR NG “DR” for small parts / granules powdering.

TALKATOR “SPC” – NEXT GENERATION

The cost-effective and dust-free solution for your technically safe process!

The TALKATOR “SPC” series for cables, hoses, wires and profiles is settled below the RSC NG line and shows its strength in slow running, simple cable production as well as in the production of strands and profiles in the extrusion sequence in the rubber industry. Especially in the rubber industry the TALKATOR has significant cost advantages, as the processes run at low speeds. This is made possible by the application of RS AirStreamTechnology, which avoids expensive brush solutions in most applications, but still provides very good coating results.

The newly developed coating technology RS AirStreamTechnology is able to achieve a very fine and even coating on the product with loaded powder at production speeds of up to 100 m/min, even without electrostatics.

For further technical data and options please refer to the chart “Technical data of the TALKATOR “SPC””.

RS AirStreamTechnology with loaded powder

Powdering of cables, hoses, wires and profiles in very slow processes

Completely newly developed machine, consistently simple

Dosed coating

Absolutely dust-free operation

“Easy Change” filter system

Optionally mobility package

Optionally compressed air dryer

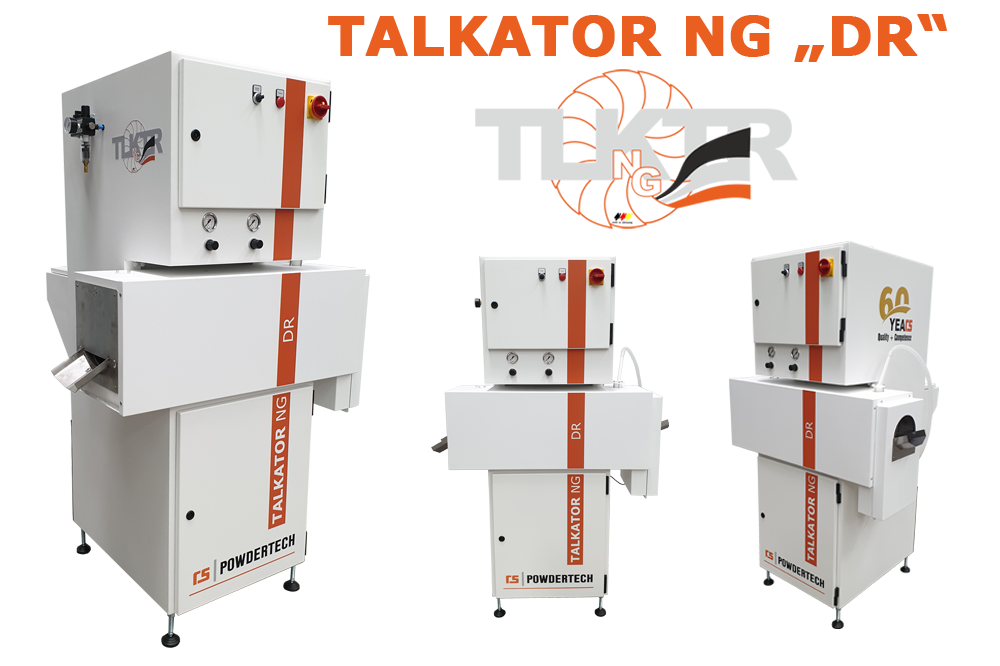

TALKATOR “DR” – NEXT GENERATION

THE dust-free automation solution for small parts and granules!

The TALKATOR NG DR (drum roll) full automation in the powdering of molded rubber parts or granulates.

Very good, fine coatings are achieved. By using the newly developed RS filter system, dust-free powdering is given, as with the PBA/RSC/RSC NG, which has been successful for many years.

The TALKATOR NG DR can be easily integrated online into automated processes. It is suitable for small and large series production.

Further technical data and options can be found in the chart “Technical data of the TALKATOR “DR””.

Powdering of ganules + small parts

Completely newly developed machine, consequently simple

Continuous process (inline)

Absolutely dust-free operation

Very fine dosed coatings

“Easy Change” filter system

Optionally mobility package

Optionally compressed air dryer

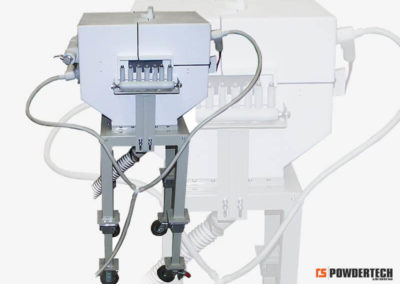

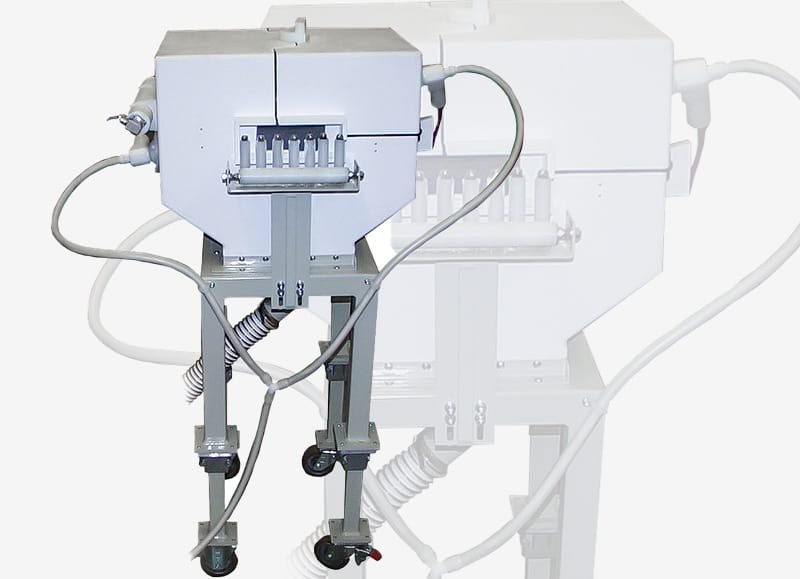

RSC – old model

RS Powdertech

Local representatives

Egypt

Pioneer Engineering

2 Yahia Sharif Street, Nozha Al Gadida, 11769 Cairo

P.O. Box 2424, Al Horeya,

Heliopolis, Egypt

Phone +20 2 26248457

Fax +20 2 26248531

alitawfik12@gmail.com

Mr. Ali Tawfik

Argentina

Rheintek Latinoamérica

Perez Valenzuela 1098, oficina 76, Providencia

Santiago de Chile 7500558, Chile

Phone +56 2 22640754

Fax +56 2 22642439

serviciocliente@rheintek-la.com

Mr. Manuel Magliotto Echenique

Armenia

Cabmash-Metiz OOO

Podolskoje Shosse, 8/5

115093 Moscow

Russian Federation

Phone +7 495 6413805

Fax +7 495 6413805

info@cabmash-metiz.ru

Mr. Nick Barinov

Azerbaijan

Cabmash-Metiz OOO

Podolskoje Shosse, 8/5

115093 Moscow

Russian Federation

Phone +7 495 6413805

Fax +7 495 6413805

info@cabmash-metiz.ru

Mr. Nick Barinov

Australia

Machinery Forum Pty. Ltd.

P.O. Box 52, 782 Heidelberg Road

Fairfield, Vic. 3078

Australia

Phone +61 3 94973633

Fax +61 3 94973188

machinery@machineryforum.com.au

Mr. Oliver Blaufelder

Belarus

Cabmash-Metiz OOO

Podolskoje Shosse, 8/5

115093 Moscow

Russian Federation

Phone +7 495 6413805

Fax +7 495 6413805

info@cabmash-metiz.ru

Mr. Nick Barinov

Bolivia

Rheintek Latinoamérica

Perez Valenzuela 1098, oficina 76, Providencia

Santiago de Chile 7500558, Chile

Phone +56 2 22640754

Fax +56 2 22642439

serviciocliente@rheintek-la.com

Mr. Manuel Magliotto Echenique

Bosnia Herzegovina

Trim d.o.o.

Ribarska 83,

35000 Jagodina

Serbia

Phone +381 35 8220-409

Fax +381 35 8224-604

office@trim.rs

Mr. Radmilo Matic

Brasil

Rheintek Latinoamérica

Perez Valenzuela 1098, oficina 76, Providencia

Santiago de Chile 7500558, Chile

Phone +56 2 22640754

Fax +56 2 22642439

serviciocliente@rheintek-la.com

Mr. Manuel Magliotto Echenique

Bulgaria

Trim d.o.o.

Ribarska 83,

35000 Jagodina

Serbia

Phone +381 35 8220-409

Fax +381 35 8224-604

office@trim.rs

Mr. Radmilo Matic

Chile

Rheintek Latinoamérica

Perez Valenzuela 1098, oficina 76, Providencia

Santiago de Chile 7500558, Chile

Phone +56 2 22640754

Fax +56 2 22642439

serviciocliente@rheintek-la.com

Mr. Manuel Magliotto Echenique

Costa Rica

Rheintek Latinoamérica

Perez Valenzuela 1098, oficina 76, Providencia

Santiago de Chile 7500558, Chile

Phone +56 2 22640754

Fax +56 2 22642439

serviciocliente@rheintek-la.com

Mr. Manuel Magliotto Echenique

Germany

ROLF SCHLICHT GmbH

Grootkoppel 16,

23858 Reinfeld

Germany

Phone +49 4533 6063-100

Telefax +49 4533 6063-101

sales@schlicht-gmbh.de

Sales Team

Ecuador

Rheintek Latinoamérica

Perez Valenzuela 1098, oficina 76, Providencia

Santiago de Chile 7500558, Chile

Phone +56 2 22640754

Fax +56 2 22642439

serviciocliente@rheintek-la.com

Mr. Manuel Magliotto Echenique

England

Barwell Global Ltd

Unit 1, 9 Burrel Road St. Ives

PE27 3LACambridge

Telefon +44 1480 832850

info@barwell.com

Estonia

ROLF SCHLICHT GmbH

Grootkoppel 16,

23858 Reinfeld

Germany

Phone +49 4533 6063-100

Telefax +49 4533 6063-101

sales@schlicht-gmbh.de

Sales Team

France

Sarl MAINEX

54 Voie Albert Einstein – Bâtiment ERIS

Parc d’activités ALPESPACE

73800 Francin

France

Phone +33 4 79366998

mainex@mainex.fr

Mr. Pascal Thomas

France

Rubber industry exclusively

LLM Maquinas caucho

Calle Pleamar 3

29720 La Cala del Moral

Spanien

Telefon +34 649 20 17 62

info@maquinascaucho.com

Georgia

Cabmash-Metiz OOO

Podolskoje Shosse, 8/5

115093 Moscow

Russian Federation

Phone +7 495 6413805

Fax +7 495 6413805

info@cabmash-metiz.ru

Mr. Nick Barinov

Greece

MBC Mediterranean Business Centre Ltd.

51, Stournara Street

10432 Athens

Greece

Phone +30 210 5234930

Fax +30 210 5226395

medbc.ltd@gmail.com

Mr. Elias Crobas

Guiana

Rheintek Latinoamérica

Perez Valenzuela 1098, oficina 76, Providencia

Santiago de Chile 7500558, Chile

Phone +56 2 22640754

Fax +56 2 22642439

serviciocliente@rheintek-la.com

Mr. Manuel Magliotto Echenique

Iran

SAMAN ANDISH Ltd.

Unit11, No38, Barazandeh Street

North Sohrevardi Avenue

Teheran 1555734151, Iran

Phone +98 21 885 30 256

Fax +98 21 885 30 257

a.shahmoradi@samanandish.com

Mr. Ahmadreza Shahmoradi

Israel

PRIMETECH

7 Abba Hillel St.

Ramat-Gan 5252204, Israel

Silver Building

Telefon +972 3 6772004

Fax +972 3 5422968

info@primetech.co.il

Mr. Chen Goldner

Ireland

Barwell Global Ltd

Unit 1, 9 Burrel Road St. Ives

PE27 3LACambridge

Telefon +44 1480 832850

info@barwell.com

Italy

Sergio Caverzaghi

Via Uberti, 6

21100 Varese

Italy

Phone +39 0332 241600

Fax +39 0332 280227

caverzaghi@caverzaghi.it

Mr. Sergio Caverzaghi

Japan

Toho International Inc.

Orix Honmachi Building 17F

1-4-1, Nishihonmachi Nishi ku

Osaka 550-0005, Japan

Phone +81 6 6543 4563

Fax +81 6 6543 4565

import@toho-intl.co.jp

Mr. Koji Yamashita

Canada

Amaral Automation

441 West Shore Rd

WARWICK RI 02889

USA

Phone +1 401 4050755

Fax +1 401 738-9800

rick@amaralautomation.com

Mr. Rick Amaral

Kazakhstan

Cabmash-Metiz OOO

Podolskoje Shosse, 8/5

115093 Moscow

Russian Federation

Phone +7 495 6413805

Fax +7 495 6413805

info@cabmash-metiz.ru

Mr. Nick Barinov

Kyrgyzstan

Cabmash-Metiz OOO

Podolskoje Shosse, 8/5

115093 Moscow

Russian Federation

Phone +7 495 6413805

Fax +7 495 6413805

info@cabmash-metiz.ru

Mr. Nick Barinov

Colombia

Rheintek Latinoamérica

Perez Valenzuela 1098, oficina 76, Providencia

Santiago de Chile 7500558, Chile

Phone +56 2 22640754

Fax +56 2 22642439

serviciocliente@rheintek-la.com

Mr. Manuel Magliotto Echenique

Croatia

Trim d.o.o.

Ribarska 83,

35000 Jagodina

Serbia

Phone +381 35 8220-409

Fax +381 35 8224-604

office@trim.rs

Mr. Radmilo Matic

Latvia

ROLF SCHLICHT GmbH

Grootkoppel 16,

23858 Reinfeld

Germany

Phone +49 4533 6063-100

Telefax +49 4533 6063-101

sales@schlicht-gmbh.de

Sales Team

Lithuania

ROLF SCHLICHT GmbH

Grootkoppel 16,

23858 Reinfeld

Germany

Phone +49 4533 6063-100

Telefax +49 4533 6063-101

sales@schlicht-gmbh.de

Sales Team

Macedonia

Trim d.o.o.

Ribarska 83,

35000 Jagodina

Serbia

Phone +381 35 8220-409

Fax +381 35 8224-604

office@trim.rs

Mr. Radmilo Matic

Mexico

Jan Ingeniería S.A. de C.V.

Miguel Angel 63

Col. Moderna

CP 03510 Del. Benito Juarez

Mexico

Phone +52 55 55546990

Fax +52 55 55496433

janingenieria@prodigy.net.mx

Mr. Javier Amaya Nava

Moldova

ROLF SCHLICHT GmbH

Grootkoppel 16,

23858 Reinfeld

Germany

Phone +49 4533 6063-100

Telefax +49 4533 6063-101

sales@schlicht-gmbh.de

Sales Team

Montenegro

Trim d.o.o.

Ribarska 83,

35000 Jagodina

Serbia

Phone +381 35 8220-409

Fax +381 35 8224-604

office@trim.rs

Mr. Radmilo Matic

Paraguay

Rheintek Latinoamérica

Perez Valenzuela 1098, oficina 76, Providencia

Santiago de Chile 7500558, Chile

Phone +56 2 22640754

Fax +56 2 22642439

serviciocliente@rheintek-la.com

Mr. Manuel Magliotto Echenique

Peru

Rheintek Latinoamérica

Perez Valenzuela 1098, oficina 76, Providencia

Santiago de Chile 7500558, Chile

Phone +56 2 22640754

Fax +56 2 22642439

serviciocliente@rheintek-la.com

Mr. Manuel Magliotto Echenique

Poland

ROLF SCHLICHT GmbH

Grootkoppel 16,

23858 Reinfeld

Germany

Phone +49 4533 6063-100

Telefax +49 4533 6063-101

sales@schlicht-gmbh.de

Sales Team

Romania

ROLF SCHLICHT GmbH

Grootkoppel 16,

23858 Reinfeld

Germany

Phone +49 4533 6063-100

Telefax +49 4533 6063-101

sales@schlicht-gmbh.de

Sales Team

Russian Federation

Cabmash-Metiz OOO

Podolskoje Shosse, 8/5

115093 Moscow

Russian Federation

Phone +7 495 6413805

Fax +7 495 6413805

info@cabmash-metiz.ru

Mr. Nick Barinov

Sweden

ECB AB

Gätisvägen 60

183 60 Täby

Sweden

Phone +46 8 890435

Fax +46 8 890435

lasse.e@ecb.se

Mr. Lasse Engström

Switzerland

ROLF SCHLICHT GmbH

Grootkoppel 16

23858 Reinfeld

Germany

Phone +49 4533 6063-100

Telefax +49 4533 6063-101

sales@schlicht-gmbh.de

Sales Team

Serbia

Trim d.o.o.

Ribarska 83,

35000 Jagodina

Serbia

Phone +381 35 8220-409

Fax +381 35 8224-604

office@trim.rs

Mr. Radmilo Matic

Slovenia

Trim d.o.o.

Ribarska 83,

35000 Jagodina

Serbia

Phone +381 35 8220-409

Fax +381 35 8224-604

office@trim.rs

Mr. Radmilo Matic

Spain

MEVAFIL

Bertran 87 S-1-2

08023 Barcelona

Phone +34 93 1144411

Fax +34 93 1170040

Spain

xvallmitjana@mevafil.com

Mr. Xavier Vallmitjana

Spain

Rubber industry exclusively

LLM Maquinas caucho

Calle Pleamar 3

29720 La Cala del Moral

Spanien

Telefon +34 649 20 17 62

info@maquinascaucho.com

South Africa

Macotech Services (Pty.) Ltd.

P.O. Box 27164, Benrose, 2011 Johannesburg

2 Julbert Road, Benrose, 2094 Johannesburg

South Africa

Phone +27 11 618 2390

Fax +27 11 614 1435

macotech@macotech.co.za

Mr. Trevor J. Hutcheon

Surinam

Rheintek Latinoamérica

Perez Valenzuela 1098, oficina 76, Providencia

Santiago de Chile 7500558, Chile

Phone +56 2 22640754

Fax +56 2 22642439

serviciocliente@rheintek-la.com

Mr. Manuel Magliotto Echenique

Tajikistan

Cabmash-Metiz OOO

Podolskoje Shosse, 8/5

115093 Moscow

Russian Federation

Phone +7 495 6413805

Fax +7 495 6413805

info@cabmash-metiz.ru

Mr. Nick Barinov

Taiwan 1

Globe Spring, Inc.

4F3, No. 85 Ching Hua Street

San Min, Kaohsiung 807

Taiwan

Phone +886 7 3878763

Fax +886 7 3868338

gsialexr@ms15.hinet.net

Mr. Alexander C.C. Lin

Taiwan 2

Grande Asia Corp.

3F, No. 36, Lane 417, Xingshan Road

Neihu District, Taipei, Taiwan, R.O.C.

Zip code: 11469

Phone +886 2 87918787

Fax +886 2 87910639

gactwn@ms13.hinet.net

Ms Denise Hsiao

Thailand

Toho International Inc.

Thailand Representative Office

2 Jasmine City Building, 25th Floor,Sukhumvit Soi 23 (Prasarn Mitr),

Sukhumvit Road, Klong Toey Nue, Wattana, Bangkok 10110

Thailand

Phone +66 61 873 3823

import@toho-intl.co.jp

Mr. Yuki Katsuno

Mr. Kazuya Okada

Tunisia

ROLF SCHLICHT GmbH

Grootkoppel 16

23858 Reinfeld

Germany

Phone +49 4533 6063-100

Telefax +49 4533 6063-101

sales@schlicht-gmbh.de

Mr. Ghassen Ben Fredj

Turkey

ES Metal San. ve Tic. Ltd. Sti.

Acibadem Cad. Rauf Pasa Sok. Derya

Aprt. No. 18/1

34660 Üsküdar-Istanbul

Turkey

Phone +90 216 3268762

Fax +90 216 3252648

eince@esmetalsan.com.tr

Mr. Eray Ince

Turkmenistan

Cabmash-Metiz OOO

Podolskoje Shosse, 8/5

115093 Moscow

Russian Federation

Phone +7 495 6413805

Fax +7 495 6413805

info@cabmash-metiz.ru

Mr. Nick Barinov

Ukraine

ROLF SCHLICHT GmbH

Grootkoppel 16

23858 Reinfeld

Germany

Phone +49 4533 6063-100

Telefax +49 4533 6063-101

sales@schlicht-gmbh.de

Sales Team

Uruguay

Rheintek Latinoamérica

Perez Valenzuela 1098, oficina 76, Providencia

Santiago de Chile 7500558, Chile

Phone +56 2 22640754

Fax +56 2 22642439

serviciocliente@rheintek-la.com

Mr. Manuel Magliotto Echenique

Uzbekistan

Cabmash-Metiz OOO

Podolskoje Shosse, 8/5

115093 Moscow

Russian Federation

Phone +7 495 6413805

Fax +7 495 6413805

info@cabmash-metiz.ru

Mr. Nick Barinov

Venezuela

Rheintek Latinoamérica

Perez Valenzuela 1098, oficina 76, Providencia

Santiago de Chile 7500558, Chile

Phone +56 2 22640754

Fax +56 2 22642439

serviciocliente@rheintek-la.com

Mr. Manuel Magliotto Echenique

United States of America

Connecticut, Maine, Massachusetts, New Hampshire, New Jersey, New York, Pennsylvania, Rhode Island, Vermont:

Amaral Automation

1697 Warwick Ave., Suite D

WARWICK RI 02889, USA

Phone +1 401 4050755

Fax +1 401 738-9800

rick@amaralautomation.com

Mr. Rick Amaral

Vietnam

Toho International Inc.

Thailand Representative Office

2 Jasmine City Building, 25th Floor,Sukhumvit Soi 23 (Prasarn Mitr),

Sukhumvit Road, Klong Toey Nue, Wattana, Bangkok 10110

Thailand

Phone +66 61 873 3823

import@toho-intl.co.jp

Mr. Yuki Katsuno

Mr. Kazuya Okada

RS Powdertech

Machine components – NEXT GENERATION

Powder pistol

Newly developed powder pistol with continuous flushing function for cleaning and reduction of wear. Exchangeable baffle plates allow adaptation to your specific product. “Poka Yoke principle” avoids mistakes during maintenance.

Powder chamber

Standard powder chamber up to 600m/min, permanently mounted or optionally freestanding. Modular system: powder chamber extra small, before stranding, high speed for up to 2000m/min.

Powder fine dosing / fine dosing “plus”

Optionally extra fine powder dosing (30 g/min) at low extrusion speed by a continuously adjustable powder conveyor. It guarantees only a smooth and even layer of powder on the product. The fine dosing „plus“ reduces the powder quantity by another 30% with a very even powdering.

Control panel

Completely newly developed e-static as well as revised control unit. Clearly arranged medical control panel with set point/actual value display, e-static and safety information. Robust, clearly arranged control panel for all further settings.

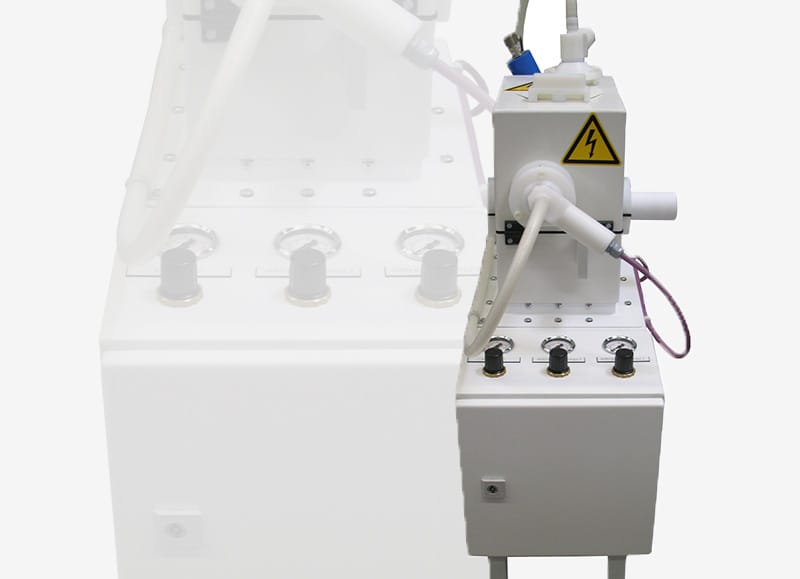

Powder flow control (optionally)

Optionally powder flow control with potential-free outlet, alarm lamp for monitoring / securing the powder feed onto the product.

Filter system

Completely revised filter system, now with “Easy Change” system for quick and smooth replacement.

Compressed air dryer (optionally)

A compressed air-dryer is installed to protect the filters, fluid base and powder.

Powder refilling hopper 90 l

Optionally an automatic 90 liter powder refilling hopper can be supplied. This powder hopper is connected with the machine by hoses. It is controlled by a level sensor inside the machine. This cart can also be used for dry storage of powder.

RS Powdertech

Machine components – TALKATOR NG “SPC”

Dust-free powdering of cables, hoses, profiles and bands in slow running production processes.

AST-Gun powder pistol (RS AirStreamTechnology)

Newly developed pistol system (world novelty), very robust, durable powder pistol.

1-2 AST pistols care for finest powdering.

Powder chamber

Exclusively permanently integrated in the machine.

Powder fine dosing

No time-consuming fine dosage, yet the new developed coating technology RS AirStreamTechnology (a world novelty) enables a wafer-thin coating.

RS Powdertech

Machine components – TALKATOR NG “DR”

Powdering of granules & small parts with highest precision.

Nozzle system

1-2 pneumatic powder nozzles.

Powder chamber

Newly developed powdering system for the continuous powdering of small parts and granulates. Excess powder on the product is removed in the process and fed back into the machine.

Exclusively permanatly integrated in the machine.

LCC series

Machine components

- Robust machine body made of steel

- Safety powder chamber

- Newly developed, easy-to-use control panel

- 1 to 2 LCC powdering “guns” (“EA=electrical applicator”), new development

- 1 to 2 R-Jet pumps, new development

- Newly developed powdering technology allows very small amounts of powder to be applied (even without micro-fine dosing), wafer-thin coating is possible

- Dust-free to the outside thanks to the newly developed LCC filter system

RS Powdertech

Machine components

100 kV powder gun

Horizontally mounted with exchangeable baffles to determine powder jet sizes.

Powder chamber

Made of 10 mm thick polystyrene with inner powder chamber to calm the vacuum air and increase the powdering quality.

Powder fine dosing

For optimal powder dosing at low extrusion speed, a continuously adjustable powder conveyor is mounted as an option to ensure that only a hint of powder is transported to the powder guns.

Control panel / powder flow indicator

With compact insert for controlling electrostatics, powder flow control and powder flow indicator with potential-free output, alarm lamp.

Powder filling/ compressed air dryer

On the back of the machine is the door for filling the machine, also during operation. A compressed air dryer is installed to protect the filters, fluid floor and powder.

Powder refilling hopper

For automatic filling of the machine a powder hopper having a volume of 90 liters is delivered and connected to the machine by a 3 m long hose. The control is made by a filling level sensor in the machine.

RS Powdertech

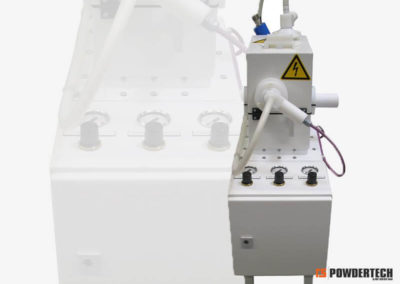

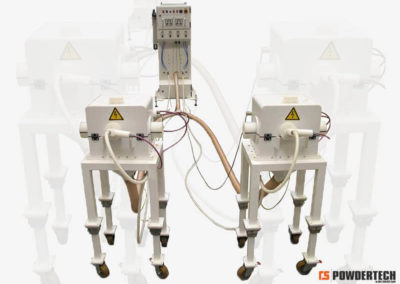

Modular system – NEXT GENERATION

We offer a number of solutions as modular system, for example.:

- extra small powder chambers

- powder chambers before stranding

- freestanding powder chambers

- purely pneumatic machines (without e-static)

- HMI/touch screen solutions (incl. recipe management)

- Full integration in lines by external interfaces

- and much more; a number of special solutions are possible

RS Powdertech

Special machines

For example: For SZ stranding machines, the free-standing powder chamber is also available with 200 mm width. The hose length between the machine and the powder chamber is max. 3 m. We also supply machines without electrostatics for simple applications such as the powdering of rubber hoses and profiles. Machines for up to 1.000 mm working width are available for powdering tapes.

RS Powdertech

Technical specifications – NEXT GENERATION

| Diameter range | up to 80 mm – standard powder chamber max. 140 mm – standard powder chamber large |

| Belts / profiles | max. 550 mm width, max. 50 mm hight |

| Electrostatics | 1 – 4 x 80 kV each pistol without losses optionally: 1 – 4 x 100 kV each pistol without losses |

| Line hight | 980 – 1.100 mm other heights on request |

| Pistols / Pneumatic Nozzles | 1 – 2 standard powder chamber 1 – 4 special powder chamber |

| Jet pumps | 1 – 4 |

| Compressed air | 6 bar |

| Filling volume | 18 l / +90 l if external powder hopper |

| Speeds | up to 600 m/min. – standard powder chamber up to 2000 m/min. – special powder chamber |

| E-connection | 3 Ph + N + PE, 400 V / 230 V, 50 Hz optionally: country-specific |

| Supply voltage | Country-specific |

| Dimensions machine | Depth: 1.706 mm Width: 800 mm Height: 1.823 mm |

| Dimensions powder hopper |

Depth: 555 mm Width: 500 mm Height: 773 mm |

| Weight | Machine: 330 kg, Powder Hopper: 35 kg |

Subject to technical modifications. Special machines are available on request.

LCC series

Technical specifications

| Diameter range: | Ø 0.1 mm to max. Ø 80 mm |

| Speeds: | 1 m/min. up to max. 350 m/min. |

| Line height: | 980 – 1,100 mm |

| Guns: | 1 to 2 LCC powdering “guns” (“EA=electrical applicator”) new development |

| Compressed air: | 6 bar |

| Filling volume: | approx. 25 l |

| Operating voltage: | Standard 3 Ph + N + PE, 400V / 230V, 50Hz; optional: country-specific |

*Technical changes reserved

RS Powdertech

Technical specifications TALKATOR NG “SPC”

| Diameter range: | v |

| Speeds: | up to max. 100 m/min. |

| Line height: | 980 – 1.100 mm |

| Pistols: | 1 – 2 AST-powder pistol (RS AirStream Technology) |

| Compressed air: | 6 bar |

| Filling volume: | approx. 18 l |

| Supply voltage: | Standard 3 Ph + N + PE, 400 V/230 V, 50 Hz optionally: country specific |

| Dimensions: | Depth: 1.110 mm (with filling), Width: 702 mm, Height: 1.778 mm |

Subject to technical modifications.

RS Powdertech

Technical specifications TALKATOR NG “DR”

| Part size: | 4 x 4 x 4 mm up to max. 80 x 80 x 80 mm |

| Powder: | All common powders |

| Line height: | 980 – 1.100 mm |

| Powdering: | Continuously, excess powder is returned |

| Compressed air: | min. 6 bar |

| Filling volume: | approx. 18 l |

| Supply voltage: | Standard 3 Ph + N + PE, 400 V / 230 V, 50 Hz optionaly: country-specific |

| Powder chamber: | Newly developed powdering system for the continuous powdering of small parts and granules. Excess powder on the product is removed in the process and fed back into the machine. |

| Dimensions: |

Machine Powder chamber |

Subject to technical modifications.

RS Powdertech

Technical specifications

| Diameter range | max. 110 mm |

| Tapes / profiles | max. 200 mm width |

| Electrostatics | 0 – 100 kV |

| Pistols | 1 – 2 |

| Jet pumps | 1 – 2 |

| Compressed air | 6 bar |

| Filling volume | 18 l |

| E-connection | 0,7 kW |

| Dimensions powder chamber | depth: 280 mm width: 510 mm height: 365 mm |

| Dimensions machine | depth: 1.140 mm width: 800 mm height: 1.942 mm |

| Weight | max. 280 kg |

Subject to technical modifications. Special machines are available on request.

RS Powdertech

Technical specifications

| Diameter range | max. 110 mm |

| Tapes / profiles | max. 200 mm width |

| Electrostatics | 0 – 100 kV |

| Pistols | 1 – 2 |

| Jet pumps | 1 – 2 |

| Compressed air | 6 bar |

| Filling volume | 18 l |

| E-connection | 0,7 kW |

| Dimensions powder chamber | depth: 280 mm width: 510 mm height: 365 mm |

| Dimensions machine | depth: 1.140 mm width: 800 mm height: 1.942 mm |

| Weight | max. 280 kg |

Subject to technical modifications. Special machines are available on request.

Contact us

Write to us by using the contact form or call us. We are happy to advise you.

Call us now

Contact us

Write to us by using the contact form or call us. We are happy to advise you.

Call us now

Our headquarters

Grootkoppel 16, 23858 Reinfeld, Germany

opening hours

Mon-Thu: 8:00 - 16:30

Fri: 8:00 - 16:00