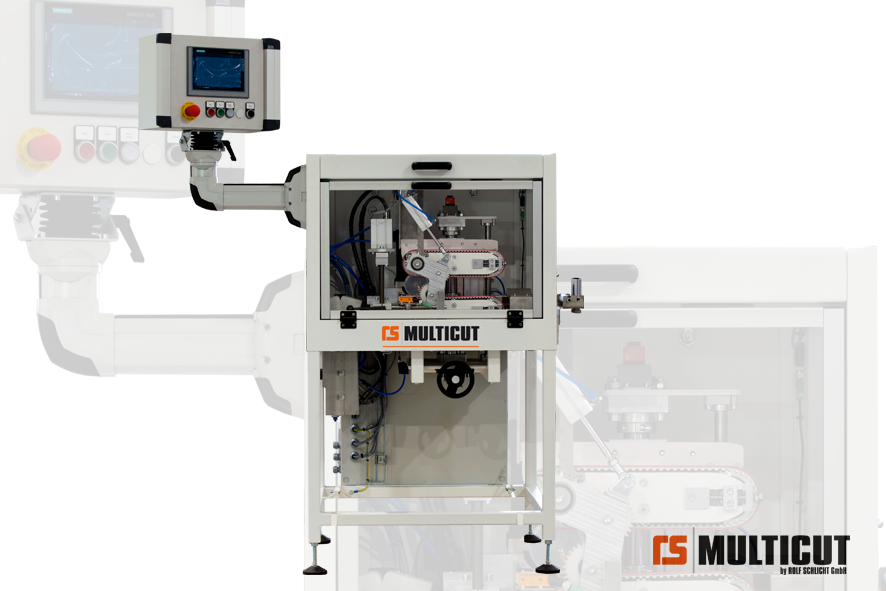

RS MULTICUT

System solutions for cutting jobs – where we do not cut, we offer a comprehensive range of semi-automatic and fully automatic winders.

Quality & Competence since 1959

Trendsetter for 65 years

Presence in more than 60 countries

RS Multicut

System solutions for all cutting tasks in the extrusion sequence – where cutting is not required, we offer an extensive range of downstream equipment.

ROLF SCHLICHT GmbH offers a wide range of system solutions for various cutting jobs in the extrusion sequence. Where we do not cut, we offer a comprehensive range of semi or fully automatic winders with strapping, setting, shrinking and ejection respectively storage on pallets or conveyor belts.

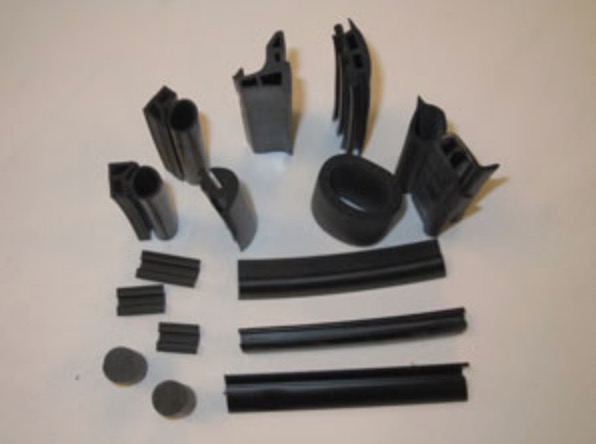

Field of application for our systems is the production area of plastic and rubber extrusion for manufacturing of hoses, tubes, profiles, strips from smallest diameter ranges to less than 1 mm in medical technology up to tubes of approx. 100 mm diameter.

We supply our feed and cutting systems also in GMP execution for the pharmaceutical industry and medical technology for the cleanroom. The systems work in the extrusion line or even outside the line from the coil, the winding band or out of the pallet.

We adapt the systems to your wishes and needs to achieve the best possible effectiveness for you.

- Trimming

- Cutting

- Cut off

- Pull off

- Transportation with or without tension

- Line independent operation by loop controls

- Discharge

- Blow off or drop off

- Collect and sort in pans, boxes, cartons or bags

CUTTING

We offer a wide range of cutting solutions for your products. From simple separation to high-precision lint and burr-free cutting with very narrow length tolerances, we can also offer solutions apart from the rubber and plastics industries. Feel free to contact us for your individual cutting solution in the extrusion sequence.

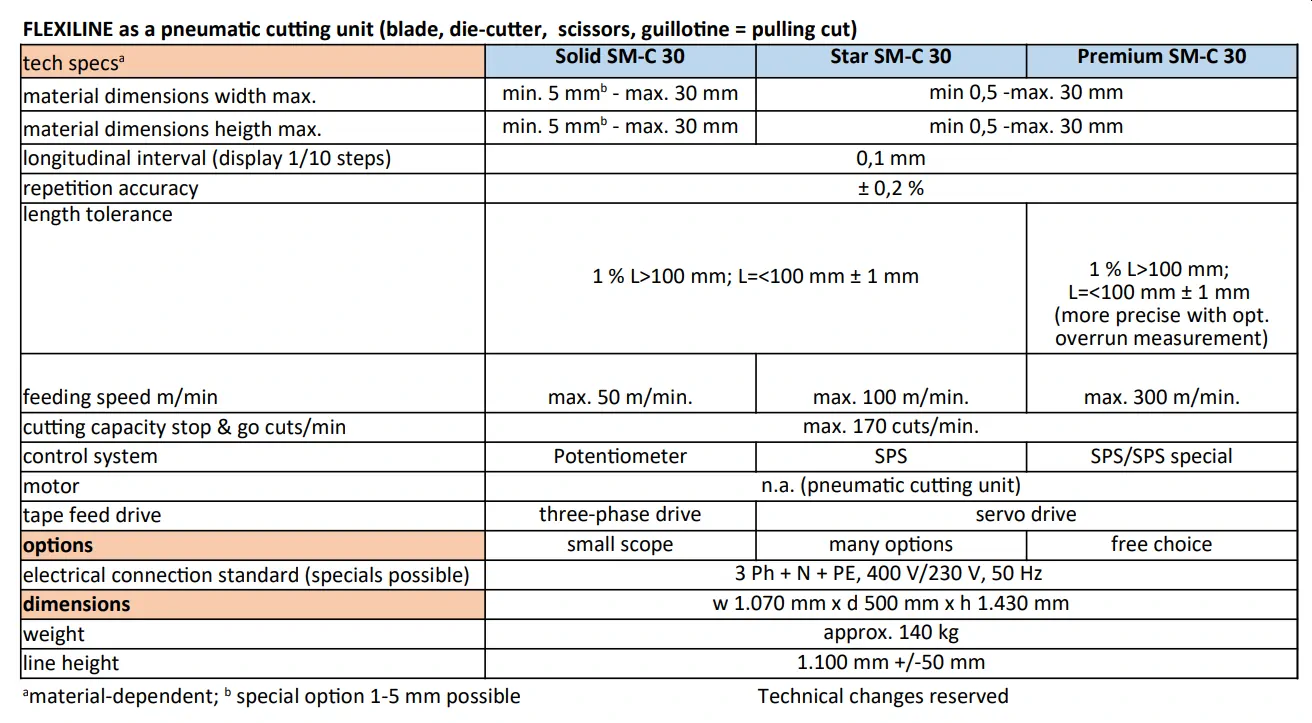

CUTTING – FLEXILINE modular system

The FLEXILINE modular system offers almost unlimited possibilities for every cutting requirement in the extrusion sequence.

Each system consists of a cutting unit and a feed. Depending on the requirements, different cutting technologies, drives, controls and additional options can be combined.

Design your individual machine from the modular system. You can choose from the “SOLID” and “STAR” series. Do you need an individual “outside the box” solution? Choose “PREMIUM” and combine the modular system with your individual special solution.

This saves costs and time.

Cutting – entry-level model EAYSYCUT

The EASYCUT is an electro-pneumatic cutting machine with a belt drive.

Cables, strands and hoses with a diameter of up to 15 mm as well as ribbon cables, tapes and foils up to 40 mm/130 mm wide can be cut. (Model 15-40 or 15-130B)

Easy handling. Optional cutting units are the wire rope and hose cutting unit.

External inputs and outputs or via RS 232. Connections for external material feed and storage devices are available.

PROCESSING SYSTEMS

As additional extrusion downstream machines, we provide high-precision RS caterpillars with servo direct drives for coupling with our cutting machines or as a “stand alone” solution. Wherever we do not cut, we can provide a wide range of semi or fully automatic winders with strapping, setting, shrinking and ejection / storage systems on pallets or conveyor belts.

Trimming Machines

Automatic trimming machines for rubber or other elastomer seals in the extrusion sequence. The machine models TGT and TGM prick or trim rubber or other elastomer seals from preforms.

SCISSOR-TYPE CUTTING SYSTEM

RS MULTICUT SC-80

RS MULTICUT SC-80 – Scissor-type cutting system with cam and servo technology for the extrusion sequence. Cutting at standstill stands for best length tolerance, angular cutting, unique cutting sequence, more than 300 cuts per minute possible. Application for profiles in the construction and furniture industry, scanner strips, semi-rigid and rigid materials.

We adapt the systems to your wishes and needs to achieve the best possible effectiveness for you.

DISCHARGE SYSTEMS

RS MULTICUT Discharge systems according to customer request

Discharge belts in the extrusion sequence for the cut parts with blow-off or discharge systems in drip trays, boxes, bags, etc. Length, width and structure of the systems are made according to customer requirements.

TRIMMING MACHINES

RS MULTICUT Series TGT

Automatic trimming machines for rubber or other elastomer seals. The machines, model TGT, cut or trim rubber or other elastomer seals. The seals are placed on rotating mandrels and are cut-off with the help of a lancing knife with highest precision. All these processes are fully automated. The loading device positions the seals to be cut and transports them to the loading grippers of the mandrels. A photocell monitors the number of seals to be cut.

Subject to technical modifications. Special machines are available on request.

TGT-35

Material: rubber

Performance: 2 cuts 800 parts/h, 1 cut 1.200 parts/h

Max. diameter: 35 mm

Max. wall thickness: 15 mm

Shaft speed: 4.000 rpm

Cutting unit: 60 mm

Cutting fine adjustment: ± 30°

Voltage standard: 400 V, 3 Ph, 50 Hz

Voltage auxiliary units: 24 V

Installed power: 0.55 kW

Compressed air: max. 6 bar

Weight: 275 kg

Dimensions: 900 mm x 1.550 mm x 1.850 mm

TGT-90

Material: rubber

Performance: 2 cuts 700 parts/h, 1 cut 1.000 parts/h

Max. diameter: 90 mm

Max. wall thickness: 20 mm

Shaft speed: 4.000 rpm

Cutting unit: 90 mm

Cutting fine adjustment: ± 30°

Voltage standard: 400 V, 3 Ph, 50 Hz

Voltage auxiliary units: 24 V

Installed power: 0.75 kW

Compressed air: max. 6 bar

Weight: 380 kg

Dimensions: 1.000 mm x 1.750 mm x 1.850 mm

TGT-140

Material: rubber-metal

Performance: depending on process

Max. diameter: 140 mm

Max. wall thickness: 20 mm

Shaft speed: 4.000 rpm

Cutting unit: 90 mm

Cutting fine adjustment: ± 30°

Voltage standard: 400 V, 3 Ph, 50 Hz

Voltage auxiliary units: 24 V

Installed power: 1,35 kW

Compressed air: max. 6 bar

Weight: 500 kg

Dimensions: 1.000 mm x 1.750 mm x 1.850 mm

Trimming Machines

RS MULTICUT Series TGM

Automatic trimming machine for cutting rubber or other elastomer hose pieces. The machines model TGM cut rotating rubber or other elastomer hoses into rings by using lance-shaped knives or circular knives.

Subject to technical modifications. Special machines are available on request.

TG-1M

Number of hoses: 1

Performance: 1x 100 cuts/min max.

Hose diameter: 210 mm max.

Hose length: 150 mm, max. 500 mm on request

Tolerance cutting unit: ± 0,01 mm

Voltage standard: 400V, 3 Ph, 50 Hz

Voltage ancillary unit: 24 V

Installed power: 1,1 kW

Weight: 300 kg

Dimensions: 790 mm x 2.000 mm x 1.650 mm

TG-2M

Number of hoses: 2

Performance: 2x 100 cuts/min max.

Hose diameter: 150 mm max.

Hose length: 150 mm, max. 500 mm on request

Tolerance cutting unit: ± 0,01 mm

Voltage standard: 400V, 3 Ph, 50 Hz

Voltage ancillary unit: 24 V

Installed power: 1,1 kW

Weight: 450 kg

Dimensions: 990 mm x 2.000 mm x 1.650 mm

TG-4M

Number of hoses: 4

Performance: 4x 140 cuts/min max.

Hose diameter: 110 mm max.

Hose length: 150 mm, max. 500 mm on request

Tolerance cutting unit: ± 0,01 mm

Voltage standard: 400V, 3 Ph, 50 Hz

Voltage ancillary unit: 24 V

Installed power: 1,1 kW

Weight: 1.100 kg

Dimensions: 1.300 mm x 2.000 mm x 1.650 mm

TG-6M

Number of hoses: 6

Performance: 6x 140 cuts/min max.

Hose diameter: 110 mm max.

Hose length: 150 mm, max. 500 mm on request

Tolerance cutting unit: ± 0,01 mm

Voltage standard: 400V, 3 Ph, 50 Hz

Voltage ancillary unit: 24 V

Installed power: 1,1 kW

Weight: 1.400 kg

Dimensions: 1.550 mm x 1.850 mm x 2.300 mm

TG-8M

Number of hoses: 8

Performance: 6x 140 cuts/min max.

Hose diameter: 110 mm max.

Hose length: 150 mm, max. 500 mm on request

Tolerance cutting unit: ± 0,01 mm

Voltage standard: 400V, 3 Ph, 50 Hz

Voltage ancillary unit: 24 V

Installed power: 1,1 kW

Weight: 1.400 kg

Dimensions: 1.550 mm x 1.850 mm x 2.300 mm

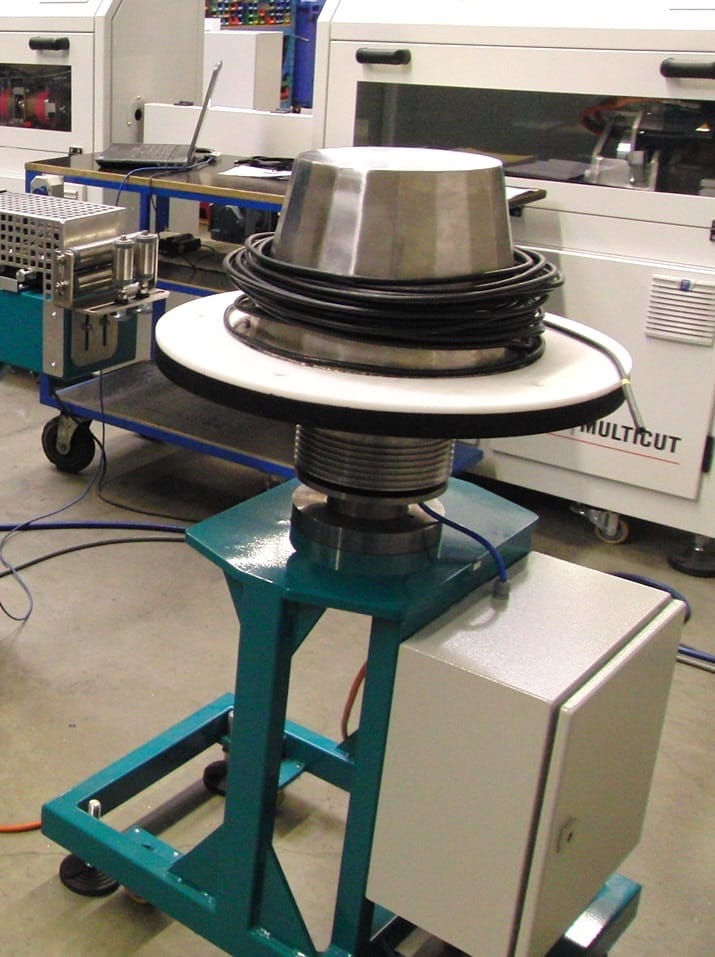

Winders

RS MULTICUT Winder according to customer request

Where we do not cut, we offer winders in the extrusion sequence with strapping, tying, shrinking as well as ejection and storage systems on pallets or conveyor belts. If you are interested in a winder, please contact us.

Turntable Winder (Example 1 according to customer request)

Turntable winder diameter: 600 mm

Turntable height: 1.000 mm

Turntable material: screen printing plate with POM ring

Max. centric load: approx. 50 kg

Drive: with three-phase asynchronous

Geared motor: approx. 0.5 kW, controlled by a frequency converter max. n = 30 1/min

Product handling: 2 transverse rolls and 2 finger rolls for product handling

Frame: steel frame, powder coated

Control cabinet: powder coated RAL 7035

2 castors

2 guide rollers

Turntable Winder (Example 2 according to customer request)

Turntable winder with 2 pins on the turntable

Turntable winder diameter: 1.600 mm

Turntable height: 800 mm

Turntable material: Birke sieve film 30 mm

Max. centric load: approx. 100 kg

Drive: with three-phase asynchronous

Geared motor: approx. 0.5 kW

Turntable speed: 1….20/min, controlled by a frequency converter, adjustable by interface 0-10 Volt

Harting plug

Connection: voltage 400 V 50 Hz 3 Ph, N, PE; 5 m connecting cable without plug

Frame: steel frame, powder coated 7021

Control cabinet: powder coated RAL 3020

4 guide rollers with brake

Turntable Winder Example 1

Turntable Winder Example 2

ORBITAL CUTTER

RS MULITCUT OC-30 NG, OC-70 NG

The orbital cutter RS MULTICUT OC-NG is suitable for semi-hard and hard pipes with a diameter of 5 to 70 mm.

The system is characterized by a clean, chip-free and right-angled cut and is used for precise and fast cutting of semi-hard and hard pipes made of plastic, rubber, plastic composite with aluminum, copper pipe inside, rubber with Kevlar, etc. The cut is done on the fly.

Thanks to a standard servo linear drive for the tool carrier, the moving cutting unit achieves excellent cutting quality and, at the same time, extremely short cycle times of around 1-2 seconds for processing high line speeds.

All important cutting parameters can be adjusted in the control during the process and optimized according to requirements. The new OC NG extrusion downstream machine is offered in the usual quality, but now at a particularly attractive price. This model is also available as high speed version OC NG HS.

A revolutionary cutting system instead of saws, guillotines etc.

Delivery of special machines on request. Subject to technical modifications

OC-30 NG

| Product diameter: |

max. Ø 29 mm |

| Product speed: | max. 12 m/min. |

| Cutting performance: | max. 25 cuts/min.* |

| Number of orbital rotations: | 3 per cut |

| Cutting motor: | Servo drive |

| Material thickness: | 6,00 mm max. |

| Operation of the blade: | mechanically by gear motor drive |

| Connection values: | 3~400 VAC, 50/60 Hz, 16 A |

| Control: | Siemens S7 |

| Used administration: | Standard |

| Line hight: |

1100 mm ±50 mm |

| Dimensions: | L 1200 mm / D 600 mm / H 1400 mm |

| Weight: | ca. 282 kg |

OC-30 NG HS

| Product diameter: |

max. Ø 29 mm |

| Product speed: | max. 20 m/min. |

| Cutting performance: | max. 50 cuts/min.* |

| Number of orbital rotations: | 3 per cut |

| Cutting motor: | Servo drive |

| Material thickness: | 6,00 mm max. |

| Operation of the blade: | mechanically by gear motor drive |

| Connection values: | 3~400 VAC, 50/60 Hz, 16 A |

| Control: | Siemens S7 |

| Used administration: | Standard |

| Line hight: |

1100 mm ±50 mm |

| Dimensions: | L 1200 mm / D 600 mm / H 1400 mm |

| Weight: | ca. 303 kg |

OC-70 NG

| Product diameter: |

max. Ø 69 mm |

| Product speed: | max. 12 m/min. |

| Cutting performance: | max. 25 cuts/min.* |

| Number of orbital rotations: | 3 per cut |

| Cutting motor: | Servo drive |

| Material thickness: | 6,00 mm max. |

| Operation of the blade: | mechanically by gear motor drive |

| Connection values: | 3~400 VAC, 50/60 Hz, 16 A |

| Control: | Siemens S7 |

| Used administration: | Standard |

| Line hight: |

1100 mm ±50 mm |

| Dimensions: | L 1200 mm / D 600 mm / H 1400 mm |

| Weight: | ca. 313 kg |

OC-70 NG HS

| Product diameter: |

max. Ø 69 mm |

| Product speed: | max. 20 m/min. |

| Cutting performance: | max. 50 cuts/min.* |

| Number of orbital rotations: | 3 per cut |

| Cutting motor: | Servo drive |

| Material thickness: | 6,00 mm max. |

| Operation of the blade: | mechanically by gear motor drive |

| Connection values: | 3~400 VAC, 50/60 Hz, 16 A |

| Control: | Siemens S7 |

| Used administration: | Standard |

| Line hight: |

1100 mm ±50 mm |

| Dimensions: | L 1200 mm / D 600 mm / H 1400 mm |

| Weight: | ca. 332 kg |

OC-30 NG

CombiCutter

RS MULTICUT Combi-Cutter CC NG

Highest cutting performance with up to 4000 cuts per minute with one knife.

The combination cutting system consists of the RB NG caterpillar haul-off and the MC NG rotary cutter from the RS MULTICUT machine series for cutting plastic and rubber profiles / hoses to length in the extrusion sequence. Both systems are perfectly coordinated.

In the caterpillar take-off, a servo motor with digital drive controllers guarantees a precise and constant transport speed of the product. The speed signal is processed internally to control the integrated rotary cutter.

The rotary cutter is an extrusion downstream machine that is used in the plastics and rubber sector to cut profiles, hoses and solid extruded profiles. Other uses such as food etc. are possible.

The product is passed through a pair of cutting bushes that can be changed quickly. The position of the bushes is monitored by sensors.

For precise cutting design, the as high as possible cutting energy of the rotary knife is required at the time of the cut. This cutting energy is achieved by means of the use of a newly developed double electronic cam disc. It accelerates the knife with every rotation so that the maximum speed is applied during the cutting process when it hits the product to be cut. The knife is then braked again to accelerate the next cycle. In interaction with the upstream transport unit, extremely precise tolerances in terms of length and squareness can be achieved, usually with a caterpillar conveyor.

A Lenze PLC control with touch screen guarantees optimal length precision. The process parameters are entered using a swiveling panel.

The rotary cutter can optionally be delivered movable, this way it can be used in the production line quickly and without major set-up effort. Depending on the profile being cut and the hardness of the material, different cutting blades and cutting bushes are used.

Segmented cutting bushes are offered to quickly meet customer requirements. They can usually be delivered within 2-3 weeks according to customer specifications. Even complex profile cross-sections can be produced very quickly without eroding.

If high demands are placed on a right-angled cut, the solution is called the clamp-cut socket (CC). Our newly developed, segmented clamp cutting bushing allows the material to be cut to be clamped and stopped for a short moment without intermittent loss of speed. This means that the material stands for a fraction of a second in the pair of cutting bushes. As a result, the tolerances are significantly smaller and the sectional view is optimized.

Advantages:

- Newly developed double electronic cam disc

- Servo drive

- Highly precise length tolerance: 1% (depending on material)

- Lenze PLC by frequency converter

- Quick change of cutting bushes

- Rectangular clean cut

- Optionally with stop & go cut or continuous cut

- Low space requirement

- Flexible to use: inline und offline

- Standard for dry and wet cut

CC-250 40 NG

s.Technical Data CC-250 40 NG :

| Tape length: | 250 mm |

| Tension: | max. 250 N |

| Material dimensions width: | max. 40 mm |

| Material dimensions height: | max. 20 mm |

| Cutting performance with one blade: | max. 4000 cuts / min.* |

| Cutting performance stop & go with one blade cycle controlled with double electronic cam disc: | max. 1450 cuts /min* |

| Length tolerance: | 1%* |

| Feed speed: | max. 100 m/min |

| Drive power: | Servo motor 3.3 KW |

| Connected load: | 400 V, 50 Hz, 3 phases |

| Control: | Lenze PLC by frequency converter |

| Operation: | operator panel |

| Perepheria interface: | yes |

| Line hight: | 1100 mm ±50 mm |

| Tape feed: | Servo motor and intergrated length measuring system |

| Dimensions (L x D x H): | 1200 x 600 x 1400 mm |

| Weight: | 430 kg |

*depending on material

Options: User management, recipe management, can be integrated in line control / inline or offline, wet cutting in stainless steel, dosable spray or drop lubrication, FDA-compliant

CC-600 40 NG

Technical Data CC-600 40 NG :

| Tape length: | 600 mm |

| Tension: | max. 800 N |

| Material dimensions width: | max. 40 mm |

| Material dimensions height: | max. 40 mm |

| Cutting performance with one blade: | max. 4000 cuts / min.* |

| Cutting performance stop & go with one blade cycle controlled with double electronic cam disc: | max. 1450 cuts /min* |

| Length tolerance: | 1%* |

| Feed speed: | max. 100 m/min |

| Drive power: | Servo motor 3.3 KW |

| Connected load: | 400 V, 50 Hz, 3 phases |

| Control: | Lenze PLC by frequency converter |

| Operation: | operator panel |

| Perepheria interface: | yes |

| Line hight: | 1100 mm ±50 mm |

| Tape feed: | Servo motor and intergrated length measuring system |

| Dimensions (L x D x H): | 1750 x 600 x 1400 mm |

| Weight: | 580 kg |

*depending on material

Options: User management, recipe management, can be integrated in line control / inline or offline, wet cutting in stainless steel, dosable spray or drop lubrication, FDA-compliant

CC-600 80 NG

Technical Data CC-600 80 NG :

| Tape length: | 600 mm |

| Tension: | max. 800 N |

| Material dimensions width: | max. 80 mm |

| Material dimensions height: | max. 80 mm |

| Cutting performance with one blade: | max. 4000 cuts / min.* |

| Cutting performance stop & go with one blade cycle controlled with double electronic cam disc: | max. 1450 cuts /min* |

| Length tolerance: | 1%* |

| Feed speed: | max. 100 m/min |

| Drive power: | Servo motor 3.3 KW |

| Connected load: | 400 V, 50 Hz, 3 phases |

| Control: | Lenze PLC by frequency converter |

| Operation: | operator panel |

| Perepheria interface: | yes |

| Line hight: | 1100 mm ±50 mm |

| Tape feed: | Servo motor and intergrated length measuring system |

| Dimensions (L x D x H): | 1750 x 600 x 1400 mm |

| Weight: | 480 kg |

*depending on material

Options: User management, recipe management, can be integrated in line control / inline or offline, wet cutting in stainless steel, dosable spray or drop lubrication, FDA-compliant

CC-1000 80 NG

Technical Data CC-1000 80 NG :

| Tape length: | 1000 mm |

| Tension: | max. 800 N |

| Material dimensions width: | max. 80 mm |

| Material dimensions height: | max. 80 mm |

| Cutting performance with one blade: | max. 4000 cuts / min.* |

| Cutting performance stop & go with one blade cycle controlled with double electronic cam disc: | max. 1450 cuts /min* |

| Length tolerance: | 1%* |

| Feed speed: | max. 100 m/min |

| Drive power: | Servo motor 3.3 KW |

| Connected load: | 400 V, 50 Hz, 3 phases |

| Control: | Lenze PLC by frequency converter |

| Operation: | operator panel |

| Perepheria interface: | yes |

| Line hight: | 1100 mm ±50 mm |

| Tape feed: | Servo motor and intergrated length measuring system |

| Dimensions (L x D x H): | 1950 x 600 x 1750 mm |

| Weight: | 730 kg |

*depending on material

Options: User management, recipe management, can be integrated in line control / inline or offline, wet cutting in stainless steel, dosable spray or drop lubrication, FDA-compliant

CombiCutterHeating

RS MULTICUT CCH-XX

CombiCutterHeating CCH-XX (5-39 mm) is a combination cutting unit in the area of the extrusion sequence with an integrated heating tunnel for cutting brittle and tough-hard materials with perfect cuts for products of min. 5 to max. 39 mm diameter.

Hard materials sometimes have the property of splintering or generating cutting chips when they are chipped if cold.

By heating the material in the inline process, we achieve a clean and chip-free cut. There is no need for expensive post-processing.

Our heating tunnel works ideally in connection with our RS MULTICUT rotary cutter MC-NG.

The heat supply is speed-controlled. In addition, an extremely fast on/off function is integrated so that the amount of heat can be precisely controlled.

Different heat levels are available for different polymer types, product sizes and line speeds.

All of our heating tunnels are fully safeguarded to protect the user and avoid the risk of fire.

Suitable polymers: impact-resistant, hard PVC, HDPE, PB, PP.

CCH-XX

Technical Data heating tunnel:

- 2 infrared panels

- Length: 500 mm

- Control device for adapting the heating power to the product speed.

- Integration into the PLC possible.

- Suitable for most plastic polymers.

- Swiveling panel

Clamp Cutting Bushes

If high demands are placed on a right-angled cut, the solution is called clamp cutting bushes!

The newly developed, segmented clamp cutting bushes enable the cutting material to be clamped inline and held for a brief moment without any loss of speed.

This means that the material stands still in the pair of cutting bushes for a fraction of a second. As a result, the tolerances are significantly smaller and the cutting pattern is optimized.

The specially developed high-speed process, which is characterized by especially high quality and cutting accuracy, is preferred for short elastomers such as precision seals.

Suitable for all hard, semi-hard and soft products, such as hoses, seals and pipes.

ADVANTAGES

- Improved squareness

- Absolutely parallel cuts with cutting lengths of 1 mm min.

- High cutting performance

- Can be retrofitted to existing MC systems

- High quality and parallelism

- Short delivery time

- Small tolerances

- Ideal for precision seals

- Improved cpk values

TECHNICAL DATA

| Product dimension: | min. Ø5 mm to max. Ø99 mm (depending on material) |

| Cutting length: | from 1 mm min. (depending on material) |

| Cutting performance with one blade: | max. 900 cuts / min. (depending on material) |

| Features:: | segmented socket |

| low vibration due to counterweight |

RS MULITCUT MCS Modular Cutting System

The MCS is a modular system for the extrusion sequence, which can be delivered in different combinations. Different modes of operation and equipment options, depending on the material to be cut, can be adapted individually and according to your wishes.

The cutting module can be changed at any time without tools, depending on the material to be cut. We offer modules for die cut, shear cut, blade cut and tool cut.

Completely individually according to your wishes.The MCS modular system is prepared for additional peripheral devices as standard.

ADVANTAGES:

- MCS with a modular concept.

- Wide range of available cutting technologies (die cut, shear cut, blade cut and tool cut)

- Tool-free quick change of the cutting modules

- Setup time optimized

MCS

Technical Data

| Cutting height: | max. 80 mm, 30 mm |

| Material width: | max. 90 mm |

| Feeding speed: | max. 60 m/min. |

| Cutting performance: | max. 55 cuts/min. (depending on material) |

| Length tolerance: | at L≥ 100 ± 1% at L≤ 100 ±1.0 mm |

| Connection values: | 3~400 VAC, 50/60 Hz, 16 A |

| Control: | Lenze PLC by frequency converter |

| User administration: | Standard |

| Dimensions: | depending on the composition |

| Weight: | depending on the composition |

Subject to technical modifications.

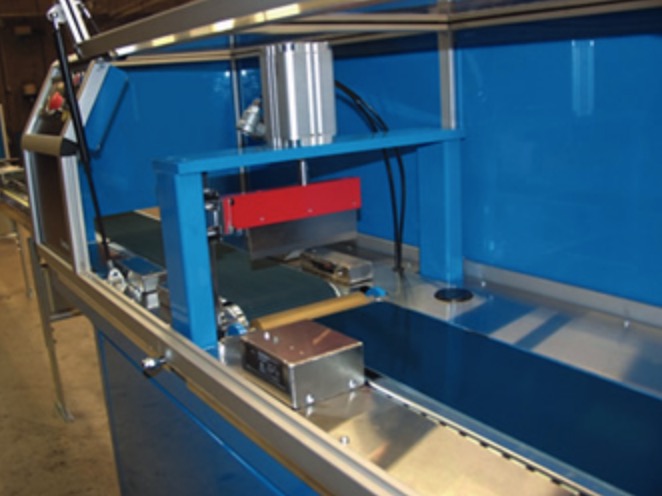

CATERPILLARS

RS MULTICUT RB-250/XXX NG, RB-600/XXX NG, RB-1000/XXX NG

The caterpillars for use in the extrusion sequence were designed to provide or transport profiles, hoses, stranded profiles, pipes and cables without slip and deformation.

Depending on the production requirement, caterpillars with a contact length of 250, 600 and 1000 mm can be chosen.

The belts are driven by servomotors. In addition, an upper drive can be selected, to achieve a slip- and deformation-free pull and an increased pulling force of the products.

The upper belt can be adjusted manually by handwheel or electrically to the product-dependent gap.

For better insertion of the products, the upper belt can be raised pneumatically by pressing a button.

For the various product materials different belt materials can be used. This guarantees a gentle deduction and transport.

Further technical data and options can be found in the table “Technical Data of the Caterpillar”

RB-250/XXX NG

Contact length: 250 mm

Belt width: 50 mm

Pulling force, dependent on max. V m/min.: 250 N (1 Drive)

Transport speed: max. 100 m/min.

Drive power: 0,37 kW

Control: Lenze

Operation: operator panel

Connected load: 400 V, 50 Hz, 3 phases

Line hight: 1100 mm ±50 mm

Dimensions: Length: 500 mm, Depth: 500 mm, Hight: 1200 mm

Weight: approx. 180 kg

Options: User management, Recipe management, Can be integrated in line control / inline or offline, Start/stop positioning, FDA conform

Technical alterations reserved. Special machines are available on request.

RB-600/XXX NG

Contact length: 600 mm

Belt width: 100 mm

Pulling force, dependent on max. V m/min.: 400 N (1 Drive), 800 N (2 Drive)

Transport speed: max. 100 m/min.

Drive power: 1.5 kW

Control: Lenze

Operation: operator panel

Connected load: 400 V, 50 Hz, 3 phases

Line hight: 1100 mm ±50 mm

Dimensions: Length: 1400 mm, Depth: 600 mm, Hight: 1400 mm

Weight: approx. 280 kg

Options: User management, Recipe management, Can be integrated in line control / inline or offline, Start/stop positioning, FDA conform

Technical alterations reserved. Special machines are available on request.

RB-1000/XXX NG

Contact length: 1000 mm

Belt width: 100/200 mm

Pulling force, dependent on max. V m/min.: 2000 N (2 Drive)

Transport speed: max. 100 m/min.

Drive power: 2.2 kW

Control: Lenze

Operation: operator panel

Connected load: 400 V, 50 Hz, 3 phases

Line hight: 1100 mm ±50 mm

Dimensions: Length: 2000 mm, Width: 600 mm, Hight: 1400 mm

Weight: approx. 350 kg

Options: User management, Recipe management, Can be integrated in line control / inline or offline, Start/stop positioning, FDA conform

Technical alterations reserved. Special machines are available on request.

Rotating Circular Knife

RS MULTICUT TE-1M, TE-2M

Automatic machines for the extrusion sequence for cutting extruded rubber or other elastomeric tubes and profiles. The TEM machines can cut extruded rubber or other elastomer tubes and profiles. The cut is made by a motorized rotating circular knife with speed control by inverter.

Subject to technical modifications. Special machines are available on request.

TE-1M

Number of knives: 1

Material dimensions/diameters: 5 mm min. – 50 mm max.

Performance: 140 cuts/min at cutting length of 50 mm, diameter 15 mm

Tension speed: max. 60 m/min

Cutting length: 1 mm – 10.000 mm adjustable, in 0,01 mm increments

Blade speed: max. 4.000 rpm, adjustable by inverter

Voltage standard: 400 V, 3 Ph, 50 Hz

Voltage ancillary unit: 24 V

Power installed: 4 kW

Weight: 1.000 kg

Dimensions: 1.100 mm x 2.050 mm x 1.900 mm

TE-2M

Number of knives: 2

Material dimensions/diameters: 5 mm min. – 50 mm max.

Performance: 2x 140 cuts/min at cutting length of 50 mm, diameter 15 mm

Tension speed: max. 60 m/min

Cutting length: 1 mm – 10.000 mm adjustable, in 0,01 mm increments

Blade speed: max. 4.000 rpm, adjustable by inverter

Voltage standard: 400 V, 3 Ph, 50 Hz

Voltage ancillary unit: 24 V

Power installed: 6,2 kW

Weight: 1.300 kg

Dimensions: 1.100 mm x 2.050 mm x 1.900 mm

ROTARY CUTTER

RS MULTICUT MC-40 NG, MC-80 NG, MC-100 NG

The rotary cutter is an extrusion downstream machine that is used in the plastics and rubber sector to cut profiles, hoses and solid extruded profiles. Other uses such as food etc. are possible.

The product is passed through a pair of cutting bushes that can be changed quickly. The position of the bushes is monitored by sensors.

The speed in continuous cutting operation depends on the selected product length, line speed and cutting speed of the cutting blade.

A Lenze control ensures perfect length precision. All process parameters can be entered by means of a swiveling panel.

The rotary cutter can be delivered movable. This way it can be used quickly and without larger setup effort in the production line. Depending on the profile cut and the hardness of the material different cutting blades are used.

Advantages:

- Newly developed double electronic cam disc

- Highly precise length tolerance: 1% (depending on material)

- Quick change of cutting bushes

- Flexible to use: inline und offline

- servo drive

- Lenze PLC by frequency converter

- Rectangular clean cut

- Swiveling panel

- Standard for dry and wet cutting

MC-40 NG

Product diameter: max. Ø 39 mm

Transport speed: max. 100 m/min.

Cutting frequency with 1 blade: max. 3.300 cuts/min (depending on material)

Cutting performance with one blade cycle-controlled with double electronic cam disc: max. 1.450 cuts/min. (depending on material)

Drive power: Servo motor 3,3 kW

Connected load: 400 V, 50 Hz, 3 phases

Control: Lenze PLC control via frequency converter

Operation: swiveling operator panel

Line hight: 1100 mm ±50 mm

Dimensions: length 700 mm, depth 600 mm, height 1350 mm

Weight: ca. 180 kg

Options: User administration, recipe management, can be integrated into line control / inline or offline, wet cutting in stainless steel, dosable spray or drop lubrication, FDA-compliant.

MC-80 NG

depthProduct dimensions: max. Ø 79 mm

Transport speed: max. 100 m/min. (depending on material)

Cutting performance with one blade continuously: 3300 cuts/min. (depending on material)

Cutting performance with one blade cycle-controlled with double electronic cam disc: max. 1450 cuts/min. (depending on material)

Drive power: Servo motor 3.3 kW

Connection values: 400 V, 50 Hz, 3 phases

Control: Lenze PLC control via frequency converter

Operation: swiveling operator panel

Line hight: 1100 mm ±50 mm

Dimensions: length 700 mm, depth 8600 mm, height 1350 mm

Weight: ca. 180 kg

Options: User administration, recipe management, can be integrated into line control / inline or offline, wet cutting in stainless steel, dosable spray or drop lubrication, FDA-compliant.

MC-100 NG

Product dimensions: max. Ø 99 mm

Transport speed: max. 100 m/min.

Cutting performance with one blade continuously: 3300 cuts/min. (depending on material)

Cutting performance with one blade cycle-controlled with double electronic cam disc: max. 1450 cuts/min. (depending on material)

Drive power: Servo motor 3.3 kW

Connection values: 400 V, 50 Hz, 3 phases

Control: Lenze PLC by frequency converter

Operation: swiveling operator panel

Line hight: 1100 mm ±50 mm

Dimensions: length 700 mm, depth 850 mm, height 1400 mm

Weight: approx. 300 kg

Optionen: User administration, recipe management, can be integrated into line control / inline or offline, wet cutting in stainless steel, dosable spray or drop lubrication, FDA-compliant.

RS GUILLOTINE CUTTER

RS MULTICUT RS NM

RS guillotine cutter series RS NM 175/60 for the extrusion sequence, equipped with pneumatically driven cutting blade, developed for rubber profiles and hoses in the middle and hard range. Machine suitable for “inline” use or outside the line. Two measuring systems for length recording are available, this means by tachogenerator / measuring wheel or photocell.

| Modell | Serie RS NM |

| Length | 4.000 mm |

| Width | 650 mm |

| Height | 1.250 mm |

| Air pressure | 6 bar |

| Power | 230/400 V |

| Max speed | 30 m/min |

| Cutting performance | 60 Schnitte/min |

| Length insertion | 10 Schnittlängen |

| Max. cutting width | 175 mm |

| Max. cutting height | 60 mm |

| Angular cutter | Nein |

| Tension | per Förderband oder Raupenabzug |

Subject to technical modifications. Special machines are available on request.

RS CIRCULAR KNIFE CUTTING SYSTEM

RS MULTICUT RS NM

RS Circular knife cutting system, series RS NM 80/45, provided with water cooling of cutting system. The machine is used in the extrusion sequence for rubber profiles with and without steel insert. When cutting the profile is held in position by means of clamping device. Equipment of the system according to customer requirements for manual or automatic use.

| Modell | Serie RS NM |

| Length | 800 mm |

| Width | 600 mm |

| Height | 1.200 mm |

| Air pressure | 6 bar |

| Power | 230/400 V |

| Max. cutting width | 80 m/min |

| Max. cutting height | 45 mm |

Subject to technical modifications. Special machines are available on request.

Rotary cut

FLEXILINE as a rotary cut

(high-speed cutting)

The FLEXILINE as a rotary cutter is made up of a cutting unit and a feed. Depending on the requirements, different drives, controls, blades and additional options can be combined.

Cutting/cutting

- directly from the extruder, winder or bar material (inline & offline)

- Hoses, profiles, tapes, strands etc.

- wide variety of materials such as rubber, plastic, medical technology products, food etc.

Rotary cutter

- Modular structure, can be combined according to process requirements

- Various drive modules, controls, caterpillar constellations

- Different cutting modes

- Various options for adapting to individual requirements

- Stainless steel body in ergonomic design, adjustable machine feet and movable

- Little need for space

- Intuitive control of process parameters via touchscreen

- Quickly changeable cutting bushings

- Highest cutting performance with up to 4,000 (6,000) cuts per minute

- Precise and constant transport speed of the product

- Excellent price-performance ratio

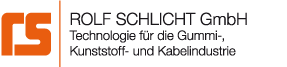

Pneumatic cutting

FLEXILINE as a pneumatic cutting unit

(blade, punch, scissors, guillotine etc.)

The FLEXILINE as a pneumatic cutting unit is made up of a cutting unit and a feed. Depending on the requirements, different cutting units, drives, controls, blades and additional options can be combined.

Cutting/cutting

- directly from the extruder, winder or bar material (inline & offline)

- Hoses, profiles, tapes, strands etc.

- a wide variety of materials such as rubber, plastic, medical technology products, food, etc.

Pneumatic cutting unit

- Modular structure, can be combined according to process requirements

- Various cutting modules, controls, caterpillar configurations

- Various options for adapting to individual requirements

- Stainless steel body in ergonomic design, adjustable machine feet and movable

- Little need for space

- Intuitive control of process parameters via touchscreen

- Quickly changeable cutting bushings

- Highest cutting performance with up to 170 cuts per minute

- Precise and constant transport speed of the product

- Excellent price-performance ratio

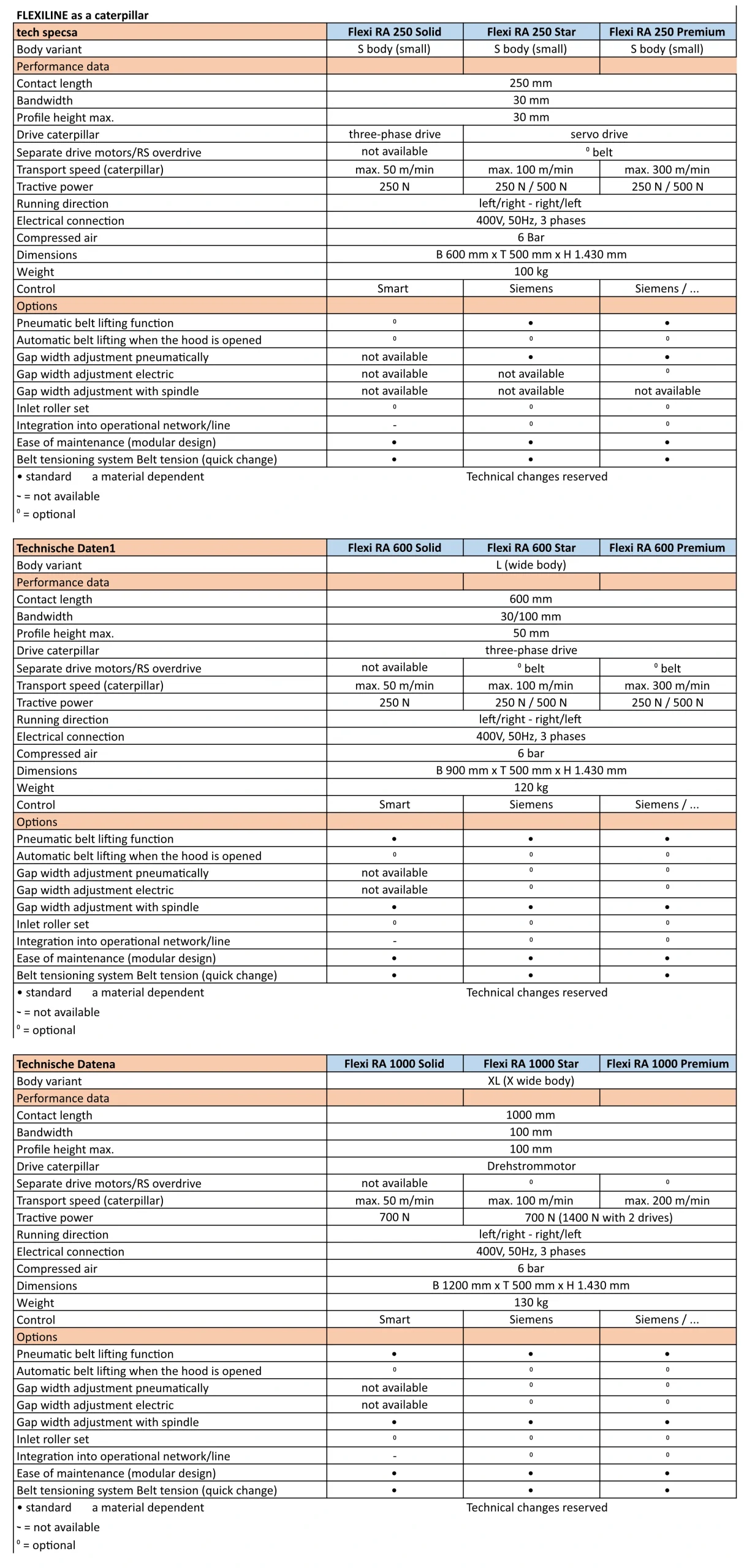

Caterpillar

FLEXILINE as a “stand alone” caterpillar

The FLEXILINE as a caterpillar is currently available in the contact lengths 250 (S body), 600 (L body) and 1000 (XL body). Depending on the requirements, different drives, controls, belts and additional options can be combined.

Pulling/transport

- Hoses, profiles, tapes, strands etc.

- wide variety of materials such as rubber, plastic, medical technology products, food etc.

Caterpillar

- Modular structure, can be combined according to process requirements

- Various controls, drive concepts/types

- Various options for adapting to individual requirements

- Stainless steel body in ergonomic design, adjustable machine feet and movable

- Little need for space

- Intuitive control of process parameters

- Precise and constant transport speed of the product up to 300m/min

- Excellent price-performance ratio

Cutting – entry-level model EAYSYCUT

Technical data EASYCUT 12 – 40

| Material diameter: | max. 15mm |

| Material width: | max. 40 mm |

| Cutting length: | 999.999,9 mm |

| Number of pieces: | 999,999 |

| Transport speed: | max. 40 m/min. |

| Cutting accuracy: ** | ±1 mm <=100 mm, ±1% >100 mm |

| Air pressure connection: | 6 bar (max. 10 bar) |

| Air pressure consumption each cycle: | 0,15 Liter |

| Voltage: * | 230 V / 50 Hz |

| Power: * | 50 VA |

| Control: * | 24 V / T1,25 A |

| Interfaces: * | feed; start/stop; printer; WTM2/deposit; external station; RS232 |

| Dimensions: | W 500 x D 470 x H 605 mm (with control) |

| Weight: | 34 kg |

*Electric machines only, **depending on material larger deviations possible. Subject to technical changes.

Technical data EASYCUT 12 – 130 B

| Material diameter: | max. 15mm |

| Material width: | max. 130 mm |

| Cutting length: | 999.999,9 mm |

| Number of pieces: | 999,999 |

| Transport speed: | max. 40 m/min. |

| Cutting accuracy: ** | ±1 mm <=100 mm, ±1% >100 mm |

| Air pressure connection: | 6 bar |

| Air pressure consumption each cycle: | 0,15 Liter |

| Voltage: * | 230 V / 50 Hz |

| Power: * | 50 VA |

| Control: * | 24 V / T1,25 A |

| Interfaces: * | feed; start/stop; printer; WTM2/deposit; external station; RS232 |

| Dimensions: | W 500 x D 550 x H 580 mm (with control) |

| Weight: | 39 kg |

*Electric machines only, **depending on material larger deviations possible. Subject to technical changes.

Contact us

Write to us by using the contact form or call us. We are happy to advise you.

Call us now

Contact us

Write to us by using the contact form or call us. We are happy to advise you.

Call us now

Our headquarters

Grootkoppel 16, 23858 Reinfeld, Germany

opening hours

Mon-Thu: 8:00 - 16:30

Fri: 8:00 - 16:00